Truck floor mats heavy duty HDPE ground protection mat

940HDPE ground protection mat

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

First of all, we need to understand the characteristics of the uhmwpe material Features of UHMWPE material:

The service life is higher than that of steel, and the wear resistance is 3~7 times that of carbon steel and stainless steel; the friction coefficient is small, self-lubricating, non-absorbent and non-stick Knot material, high impact strength, good comprehensive mechanical properties, acid, alkali, salt corrosion resistance, no aging, low temperature resistance, hygienic Poisonous, light weight, the specific gravity is 1/8 of steel. Therefore, it is the best material for lining of bulk material storage and transportation equipment, such as Storage bins, launders, etc. Widely used in electric power, steel mills, coal mines and other industries.

UHMWPE sheet has high wear resistance, corrosion resistance, impact resistance, self-lubricating, and can be used to make coal, cement, lime,Lining of hoppers, silos and chutes for mineral powder, salt, grain-like powdery materials. Because of its excellent wear resistance, self-lubricating.

It has good properties and non-stickiness, so that the above-mentioned powder materials will not stick to the storage and transportation equipment and ensure stable transportation.

In order to adapt to the installation and application under various environmental conditions, this kind of high wear-resistant sheet can be designed to be assembled and connected according to user requirements.

Customized for easy installation and maintenance. Such as the installation of hoppers and chutes underground in coal mines with very difficult operating conditions, and the leakage of materials in the metallurgical industry.

The application of buckets, etc., can completely solve the long-standing problem of sticking and material blocking in the conveying process, and realize safe, efficient and normal production.

Application field: It can be widely used in the transportation of liquid,Solid, solid-liquid mixture hopper, funnel, flap, slideway of scraper conveyor, sieve plate of jig, flotation machine liner, boat Wear-resistant and anti-corrosion applications for ship cargo compartment linings, large sliders, mining trucks, dump truck linings, etc., with unique value-for-money

Advantage.

Scope of use:

Chemical Engineering: Corrosion and Wear Resistant Mechanical Components

Thermal power generation: coal transportation, coal storage, storage chute lining

Coal processing: sieve plate, filter plate, underground U-shaped coal mining chute

Concrete: Cement raw silos and finished silos lining

Grain: Grain silo storage chute lining

Mining: screen decks, chute linings, wear resistant and anti-stick sections

Food industry: star wheel, timing screw for conveying bottles, bearings, guide rollers, guide rails, slider seats, etc.

Military industry: shielding for military protection, equipment parts for impact Nuclear power plants: shielding against radiation sources.

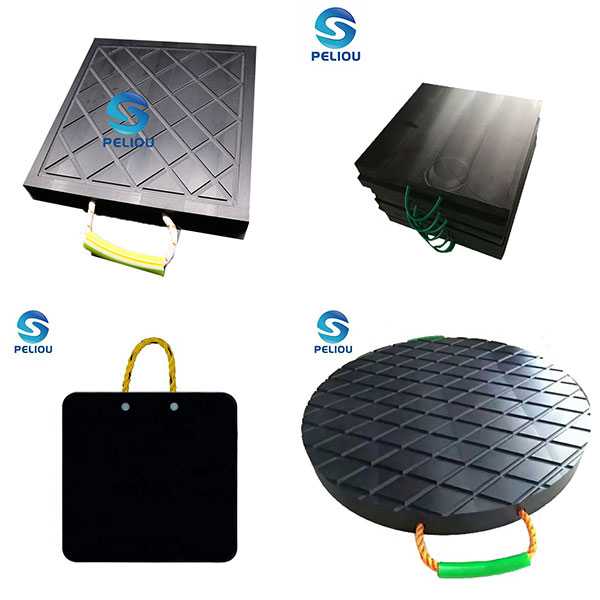

And UHMWPE Outrigger Pads are made of this material, so it is very environmentally friendly and convenient, please see the picture below .

UHMWPE Outrigger Pads are widely used in engineering sites as crane pads,

We can customize the thickness you need according to your load-bearing requirements,

Welcome Inquiry !

More and more people see the advantages of HDPE ground protection mats and start to use HDPE ground protection mats. Today's article will introdu...

View detailsHi, my dear friend. How do you know the black ground protection mats are one of our best selling products? That's good judgment. So today let me in...

View detailsLiberty ground protection mats, it can be quickly installed wherever it is needed without being limited by time and space, and become a temporary r...

View details

Your article helped me a lot, is there any more related content? Thanks!

2024-12-22下午2:45

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

2025-01-06下午3:14

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

2025-01-19下午5:05