What is polyethylene road mat?

545polyethylene road mat

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

Crane leg pads, also known as outrigger pads, crane pads, or stabilizer pads, play a crucial role in enhancing safety and efficiency in crane operations. These pads are placed under the crane’s outriggers, which are extendable legs that help distribute the crane’s load and provide stability during lifting operations. Here are the key advantages of using crane leg pads:

1. Increased Stability and Safety

– Crane leg pads distribute the load of the crane over a larger area, reducing the ground pressure which can prevent outriggers from sinking into soft ground. This distribution is vital for maintaining the crane’s stability, especially when lifting heavy loads, and significantly reduces the risk of accidents.

2. Protection of Ground Surfaces

– Without the use of pads, the intense pressure from the outriggers can damage road surfaces, pavements, and other sensitive areas where cranes need to operate. Crane leg pads help protect these surfaces from being indented, cracked, or otherwise damaged by spreading out the pressure.

3. Enhanced Load Distribution

– The pads are designed to spread the load more effectively than the outriggers alone, especially on uneven or unsteady surfaces. This feature is critical for operations in areas where the ground consistency varies.

4. Reduced Costs

– By preventing ground damage and enhancing crane stability, crane leg pads help reduce potential repair costs for ground surfaces and decrease the likelihood of crane-related incidents that could lead to costly downtime and repairs.

5. Versatility

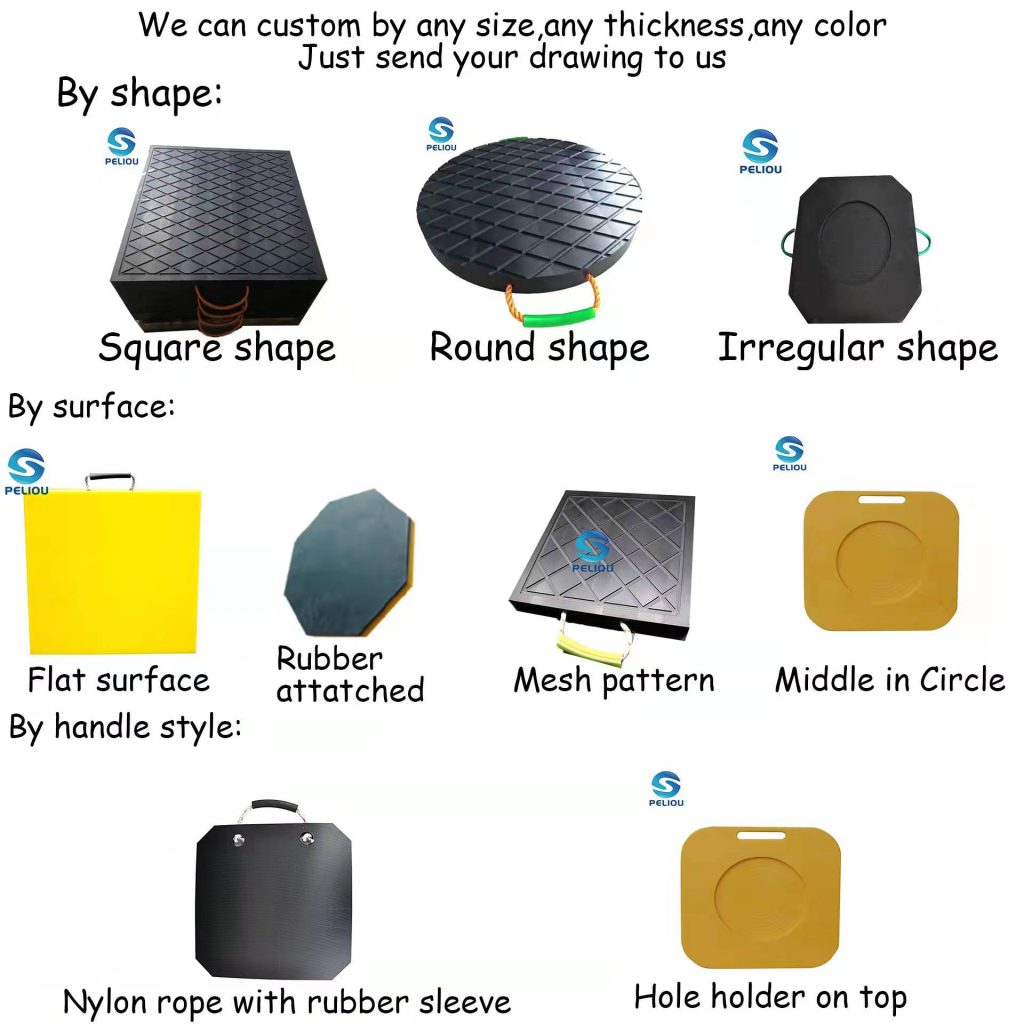

– Crane leg pads are made from various materials, including high-performance polymers and steel, and come in different sizes and thicknesses to accommodate different crane models and load requirements. This versatility ensures that operators can select the most appropriate pads for their specific needs, making them suitable for a wide range of environments and ground conditions.

6. Ease of Use and Portability

– Many crane leg pads are designed with handles or are made from lightweight materials, making them easy to transport and position under the crane’s outriggers. This ease of use improves setup times and overall efficiency on the job site.

7. Longevity and Durability

– Materials used in crane leg pads, such as UHMWPE (Ultra-High Molecular Weight Polyethylene) or reinforced rubber, are highly durable and resistant to water, chemicals, and UV light. This durability ensures a long service life, even in harsh environmental conditions.

8. Improved Operational Efficiency

– By enabling cranes to operate safely on a wider variety of ground conditions, crane leg pads allow for greater flexibility in planning and executing lifting operations. This flexibility can lead to improved operational efficiency and productivity.

In summary, the use of crane leg pads is an essential practice in crane operations for enhancing safety, protecting ground surfaces, and ensuring efficient and productive lifting activities. Their benefits justify their inclusion as a standard part of equipment for crane operators in various industries.

It’s time for product recommendation once a week again. Today I’m going to introduce to you the king of sales this month----outrigger pads. Hope th...

View detailsThe polymer coal bunker liner not only has the characteristics of increasing slip, but also has the characteristics of wear resistance and buffering. After years of careful research on coal blocka...

View details

This is a topic which is near to my heart… Take care!

Exactly where are your contact details though?

My site :: драгон мани казино официальный

2025-02-04下午6:32

I must thank you for the efforts you’ve put in writing this site.

I am hoping to check out the same high-grade content by you in the future as well.

In fact, your creative writing abilities has motivated me to get my own, personal website now 😉

Here is my page – máy hút bụi công nghiệp

2025-02-04下午7:46

I have been surfing on-line more than 3 hours these days, but I never found any attention-grabbing article like yours.

It is pretty price sufficient for me. Personally, if all webmasters and bloggers made good content as you

probably did, the web will likely be much more useful than ever before.

Also visit my webpage :: máy nén khí

2025-02-04下午8:01

Hello there I am so grateful I found your site, I really

found you by mistake, while I was browsing on Digg for something else,

Anyhow I am here now and would just like to say thanks for a

incredible post and a all round exciting blog

(I also love the theme/design), I don’t have time to read it

all at the moment but I have book-marked it and also added in your RSS feeds, so when I have time I will be back to read much more, Please do keep up

the awesome b.

Feel free to visit my blog – kopikap.pro

2025-02-04下午8:14

Greate pieces. Keep posting such kind of information on your

site. Im really impressed by it.

Hey there, You’ve performed an excellent job. I’ll certainly

digg it and individually suggest to my friends.

I’m sure they will be benefited from this web site.

Here is my blog post; HI88

2025-02-05下午2:36

I know this if off topic but I’m looking into starting my own weblog and was curious what all is

needed to get setup? I’m assuming having a blog like yours would cost a pretty penny?

I’m not very web smart so I’m not 100% positive.

Any tips or advice would be greatly appreciated.

Kudos

my homepage: https://donovanjijg33109.tnpwiki.com/6582107/the_advantages_of_premium_performance_enhancers_for_athletic_excellence_and_wellness

2025-02-06上午7:52

I know this if off topic but I’m looking into starting my own weblog and was curious what

all is needed to get set up? I’m assuming having a blog like yours would cost a pretty penny?

I’m not very internet smart so I’m not 100% positive. Any recommendations or advice would be greatly appreciated.

Many thanks

Review my site; new sight eye care

2025-02-06下午5:45

I’m very pleased to uncover this web site. I want to to thank you for your time for this particularly fantastic

read!! I definitely loved every little bit of it and i also have

you saved to fav to see new information in your site.

Also visit my web page – doa setelah sholat

2025-02-07上午9:43

Pretty section of content. I just stumbled upon your blog and in accession capital to claim that I

get actually loved account your weblog posts. Anyway I’ll

be subscribing in your augment or even I fulfillment you access consistently quickly.

My blog post … ide777

2025-02-07下午5:54

Hello friends, its wonderful piece of writing regarding cultureand fully defined, keep it up all the time.

My web blog … PENIPU

2025-02-12下午4:43

A person essentially lend a hand to make critically posts I might state.

That is the very first time I frequented your web page and

up to now? I amazed with the research you made to make this particular submit amazing.

Fantastic job!

My blog – video mesum anak kecil

2025-02-13上午2:40

Hello, I think your site might be having browser compatibility issues.

When I look at your blog in Opera, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up!

Other then that, great blog!

Feel free to visit my web blog: no deposit casino bonus

2025-02-13下午1:25

These are actually enormous ideas in on the topic

of blogging. You have touched some good things here.

Any way keep up wrinting.

My homepage: PENIPU

2025-02-14上午11:52

1 Win est une plateforme renommée pour les jeux de pronostics et les divertissements de casino virtuel en Côte d’Ivoire.

Son popularité repose sur une ergonomie bien pensée, des probabilités attractives et une vaste sélection de jeux adaptés aux préférences

des amateurs de jeux en RCI. Grâce à une autorisation réglementée, elle garantit un environnement de

jeu protégé, attirant chaque jour de nouveaux utilisateurs désireux de

tenter leur chance.

Les paris sportifs sur 1 Win offrent de nombreuses compétitions, incluant le soccer

et l’e-sport en passant par le basketball et le tennis.

Les utilisateurs peuvent engager des mises avant le début des matchs ou en direct, tirant avantage des variations de cotes pour maximiser leurs gains.

La plateforme propose également des options de paris multiples, permettant aux joueurs d’augmenter

leurs gains potentiels en combinant plusieurs événements sur

un même ticket.

La section casino de 1Win est un autre pôle d’intérêt, offrant

une aventure captivante avec une multitude d’options incluant des slots et des jeux de table tels que le blackjack, la

roulette et le poker. Les slots avec avantages sont très populaires, puisqu’elles proposent des parties gratuites et de

tenter de décrocher des jackpots progressifs.

Les amateurs de jeux de table adorent les sessions en streaming animées par des croupiers professionnels, ajoutant une touche d’authenticité.

Les utilisateurs bénéficient d’une connexion grâce à

leur moteur de recherche ou avec l’appli disponible, garantissant une expérience utilisateur optimale.

Les joueurs peuvent miser aisément avec l’appli, n’importe où, et de découvrir des bonus exclusifs sur l’application. L’enregistrement se fait en quelques instants,

donnant accès immédiatement aux paris.

Cette plateforme devient une référence dans l’univers des jeux d’argent

en ligne en Afrique de l’Ouest. Grâce à ses nombreux atouts, incluant une sélection de jeux variée et des offres avantageuses, le service est à la hauteur des exigences des joueurs https://1-win.ci/ , leur offrant une expérience à la fois

passionnante et rentable.

2025-02-14下午12:37

Hey! I’m at work browsing your blog from my new iphone 3gs!

Just wanted to say I love reading through your

blog and look forward to all your posts! Carry on the fantastic work!

my blog post – blog here

2025-02-14下午3:48

Distributor Besi Terpercaya , Distributor Sinar Baja Murah Medan,

Besi Baja Terpercaya , Baja Ter murah Kota Medan, Besi Terlengkap Kota Medan

Take a look at my site; Harga Besi Hollow Galvanis Medan: Panduan Lengkap untuk Pembelian dan Keuntungannya

2025-02-15上午12:42

Thank you for the good writeup. It in fact was

a amusement account it. Look advanced to more added

agreeable from you! By the way, how can we communicate?

My site – video mesum anak kecil

2025-02-15上午1:30

Wow that was odd. I just wrote an incredibly long comment but after I clicked

submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyways, just wanted to say fantastic blog!

Feel free to surf to my web-site; check my reference

2025-02-15上午2:39

Thanks a bunch for sharing this with all folks you actually understand what you

are talking approximately! Bookmarked. Please also talk over with

my site =). We could have a hyperlink trade arrangement between us

Here is my blog post – Instant X4 Bumex

2025-02-15上午6:45

I read this paragraph fully concerning the resemblance of

newest and preceding technologies, it’s remarkable article.

Also visit my web page – sex vietnam

2025-02-15上午8:38

Good post. I definitely love this site. Continue the good work!

Feel free to surf to my website :: Instant +200 Day Pro

2025-02-15下午7:27

Hurrah, that’s what I was exploring for, what a information! present here at this

webpage, thanks admin of this website.

My site – PENIPU

2025-02-16下午1:10

{Usually, you can get a match deposit welcome bonus with free

spins to play online new slots.|However, it’s essential to use this feature wisely and be

aware of the potential risks involved.|For cryptocurrency users,

Slots LV offers enhanced bonuses, making it an attractive option for those looking to play with digital currency.|Moreover, these

RNG-tested games ensure a fair gambling experience for every player.|Another subcategory of

video slots that deserves special mention is the altogether rather narrow

group of games dedicated to music.|There are many slot machine apps available for iPhone and Android OS and they almost all work

the same way.|Best video slot machines combine high RTP with

innovative features.|You do have the potential

to receive bonus offers to play real money casino games, but free

slots for fun do not payout real money.|This feature typically

involves guessing the color or suit of a hidden card

to double or quadruple your winnings.|Remember

that playing with Sweeps Coins gives you a chance to redeem for cash prizes and gift cards

at this leading site.|RAM and ROM size do not affect overall performance with the modern mobile compatibility settings.|With

5 reels and 25 pay lines, there are numerous chances

to land winning combinations.|Given that online casinos show many benefits to gamers, players can enjoy a range of slots for fun these days.|Some modern 5-reel

slots have expandable reels that can accommodate thousands of win ways.|You cannot retrigger

Re-Spins during the feature, nor can you activate the Pegasus

Bonus or the Once Bitten Bonus features during Re-Spins.|If you manage to land two wilds, your winnings will be quadrupled.|When you find a perfect 3D casino online for you,

be sure to register.|If you’re looking for the 3D slots with the highest RTP,

you’re in the right place!|In each of these spins, your chances of winning will be boosted, usually thanks to extra in-game features, boosted reels,

or multipliers.|The value tells how much of the total stake will be paid out to the players in the long run.|Produced by Light &

Wonder, this game builds on its predecessor’s success with an additional wheel for enhanced prizes.|For

example, a 3D Slots machine with a 90% RTP will pay £90

back out for every £100 put in, leaving the casino with a 10% cut.|Another entry courtesy of Microgaming, Frozen Diamonds has not received the recognition it deserves.|It’s

a combination of advanced graphics, immersive sound design, and interactive elements that create a multi-layered experience.|Recently, however, there has been an entirely new category of slot

games that started to get attention amongst online

gamblers, and that is 3D slots.|One of the most popular BetSoft slots

is The Slotfather, known for its engaging gameplay and unique theme.|It created two of the most iconic

casino games of all time – Starburst and Gonzo’s Quest – along with slots like Twin Spin, Reel Rush, Narcos, Dead or Alive, and Mega Fortune.|Imagine playing

a slot game where you are transported into the virtual world, able to

interact with the game environment in a fully immersive experience.|If you don’t know exactly what this means, we are here to explain.|You can still expect fewer paylines from these modern classic online slots, which ensures betting totals remain low

while winning potential always impresses.|In addition, popular themes on US slot sites include pets, carnivals, fairytales,

and luxury.|If you deposit with prepaid cards, you’ll need

to choose a different cashout option, such as e-wallets.|Let’s take a look

at some of the top titles in the market, known for their

stunning visuals, engaging storylines, and

exciting gameplay.|Engage your punters and customers with the

provided fascinating effects that come along with our slot game development services.|With such fierce

competition between casinos, they can’t afford to be

offering low payouts – especially Online betting (online-casinos.club) where

customers only need to switch websites to get a better percentage.|Cascading

reels replace traditional spinning reels with falling symbols.|Bowen specializes in writing on a variety of subjects, including roulette, blackjack, video poker,

sports betting, and more.|When choosing 3D slots to play, it’s important to consider the quality of the software providers.|Social slots are a

great way for new players to understand the mechanics and rules without financial risk.|It’s the place where both the rookie and

the old-hand slot players find common ground in user-friendly interfaces

and butter-smooth gameplay.|The jackpot could be fixed (a pre-set amount for all

players) or progressive (an increasing pool donated by bets).|This machine

only had three drums (now known as reels) and five symbols.|You receive a prize for

every number you bet on that matches the winning numbers.|For a long

time, playing online slots for real money was not legal in the US.|The company

develops software for land-based IGT casinos, mobile systems and

online casinos.|You have as much chance of winning

as an experienced player, it just depends how the reels land.|For over 20 years, we have been on a mission to help slots players find the best

games, reviews and insights by sharing our knowledge and expertise in a fun and friendly way.|BetMGM provides everything a player could need

from a slots site.|Mechanics vary, so read all

about it to learn how to participate.|These slots feature five

or more reels and a larger number of paylines compared to the classic

ones, offering you more opportunities to win.|Gold Rush Gus offers

a cartoonish mining adventure with engaging graphics

and interactive gameplay.|Bonus features not only boost the fun of free

slots, they also enhance their unique story and world.|Rest assured that we will only recommend legal online slots

sites that carry the necessary licenses in the states they operate.|To give

you the best user experience every time you play,

our dedicated customer support team is always on standby and ready

to assist you with any questions you may have.|You don’t need much to enjoy the excitement of playing slots online.|A lot of

our players say that once you discover the fun to be had, you’ll never want to go back to plain old slots.|Medusa offers

a Gamble feature that affords winning spins the opportunity to double or quadruple that payout.|Some slots already allow toggling background music or sound effects on/off.|While 2D slots are

colourful and fun to look at, they don’t feel as good as a 3D slot.|Some

casinos pack a punch with tons of slots, a mix of different game providers, and even some exclusive titles you won’t find anywhere else.|If you’re wondering how to play slot machines in a way to

increase your Chances to Win, be aware of the

following tips.|The slot machine has 6 bonus features with a varying number of free spins.|The free slot machines are

identical by their operation to regular slots found in online casinos.|If you instead

land the Monkey symbol right in the middle of the grid, the Click Me Crazy!|If

you enjoy slots with immersive themes and

rewarding features, Book of Dead is a must-try.|This is available in demo mode, and it’s a

perfect example to get familiar with the game’s features

without any risk.|In general terms, yes, except that you don’t

have the option to play for real money in free slots.|Enjoyable gaming session by first

understanding the rules of the game.|Known for its vibrant graphics and fast-paced gameplay, Starburst offers a high RTP of 96.09%, which makes

it particularly attractive to those looking for frequent wins.|On this page, you will find

a complete list of slots collected by SlotsUp’s team since 2015.|The legendary Mega Moolah slot has repeatedly made headlines,

with a Belgian player landing a staggering $23.6 million jackpot in April 2021.|Each game

is a doorway to a new realm, waiting for you

to step in and claim its treasures.|The element of surprise and the fantastic gameplay

of Bonanza, which was the first Megaways slot, has led to a wave of classic slots reinvented using this format.|Whereas there can be hundreds of games inside land casinos, there can be thousands

of games in an online casino.|We give you the option of a

fun, hassle-free gaming experience, but we will be by your side if you choose something different.|Selecting the right online casino is crucial for a safe and enjoyable

gaming experience.|With

2025-02-16下午2:32

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

2025-02-16下午9:52

Hello Dear, are you in fact visiting this website regularly,

if so afterward you will definitely obtain nice know-how.

Also visit my web site: gaziantep su tesisatı

2025-02-17上午10:59

hello there and thank you for your information – I’ve definitely picked up anything

new from right here. I did however expertise several technical points using this website, since I experienced

to reload the website many times previous to I could get it to load

correctly. I had been wondering if your web hosting

is OK? Not that I’m complaining, but sluggish loading instances times will sometimes affect your placement

in google and could damage your quality score if advertising and marketing with Adwords.

Anyway I am adding this RSS to my e-mail and could look out

for a lot more of your respective interesting content.

Make sure you update this again soon.

Here is my blog – selling digital products

2025-02-17下午12:54

These are actually fantastic ideas in about blogging.

You have touched some pleasant factors here. Any way keep up wrinting.

Feel free to surf to my blog: mardin haberleri

2025-02-17下午6:21

Amazing blog! Do you have any tips and hints for aspiring

writers? I’m hoping to start my own website soon but I’m a little lost on everything.

Would you propose starting with a free platform like WordPress or go

for a paid option? There are so many options out there that

I’m completely confused .. Any recommendations?

Bless you!

Also visit my web-site :: dp instagram download

2025-02-18上午8:23

I am really loving the theme/design of your weblog.

Do you ever run into any internet browser compatibility problems?

A handful of my blog audience have complained about my blog not

working correctly in Explorer but looks great in Firefox.

Do you have any advice to help fix this problem?

My blog – ecommerce

2025-02-18上午8:35

May I simply say what a relief to discover a person that genuinely understands what they are talking about on the web.

You actually know how to bring a problem to light

and make it important. More and more people really need to check this out and understand

this side of your story. I was surprised you’re not more popular since you

surely have the gift.

Also visit my website: best bitcoin casinos

2025-02-18下午11:36

I like the helpful info you provide in your articles. I will

bookmark your blog and check again here frequently. I am quite certain I will learn lots of new stuff right here!

Best of luck for the next!

Review my web-site – Fun Bet Casino Win

2025-02-19上午4:15

There is definately a great deal to find out about this issue.

I like all the points you’ve made.

Here is my webpage; PENIPU ONLINE

2025-02-19上午5:32

I will right away clutch your rss as I can not to find your e-mail subscription hyperlink or newsletter service.

Do you have any? Please let me recognise in order that I may

subscribe. Thanks.

Also visit my web page: cryptocurrency

2025-02-19下午1:21

Woah! I’m really digging the template/theme of this blog.

It’s simple, yet effective. A lot of times it’s

very hard to get that “perfect balance” between user friendliness and visual appeal.

I must say that you’ve done a superb job with this. Also,

the blog loads extremely quick for me on Chrome. Outstanding Blog!

Here is my website … kayseri masaj salonu

2025-02-20上午3:42

I believe that is among the most important information for me.

And i am happy reading your article. But should observation on some common issues,

The website taste is wonderful, the articles is truly excellent : D.

Excellent process, cheers

Here is my web blog :: PENIPU ONLINE

2025-02-20上午7:47

My brother recommended I may like this web

site. He was entirely right. This publish truly made

my day. You cann’t consider just how so much time I had spent for this information! Thanks!

Also visit my blog – photo tiktok download

2025-02-20上午8:23

Hi there would you mind stating which blog platform you’re working with?

I’m planning to start my own blog soon but I’m having a tough time deciding between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design and style seems different then most

blogs and I’m looking for something completely unique.

P.S My apologies for being off-topic but I had

to ask!

Feel free to visit my web blog; MACAUSLOT88

demo (macauslot88l1.pro)

2025-02-20下午7:30

First off I want to say great blog! I had a quick question in which

I’d like to ask if you do not mind. I was interested to know how you center yourself and clear your mind

prior to writing. I have had trouble clearing

my thoughts in getting my ideas out there. I do take pleasure in writing but it just seems like the first 10

to 15 minutes tend to be lost simply just trying to figure out how to begin. Any ideas or tips?

Kudos!

Check out my web page: SHBET

2025-02-20下午9:41

Touche. Great arguments. Keep up the amazing work.

Feel free to visit my blog youtube download qawwali

2025-02-20下午11:33

This post is priceless. When can I find out more?

Look at my web site … пинко казино официальное

2025-02-21上午3:41

Link exchange is nothing else but it is simply placing the other person’s webpage link on your

page at suitable place and other person will also do similar in favor of you.

Also visit my site; s19 pro for sale

2025-02-21上午4:46

I enjoy what you guys tend to be up too. This kind of clever work

and coverage! Keep up the terrific works guys I’ve added you guys

to blogroll.

Here is my blog post: important source

2025-02-21上午5:23

Good day! This is my first visit to your blog!

We are a group of volunteers and starting

a new initiative in a community in the same niche. Your blog provided us useful information to work

on. You have done a outstanding job!

Feel free to surf to my blog – Backlinks Coupons

2025-02-21下午4:09

Wow, marvelous weblog format! How long have you ever been running

a blog for? you make blogging look easy. The overall glance of your web site is wonderful, as smartly as the

content!

Feel free to surf to my page – PENIPU ONLINE

2025-02-21下午4:58

outdoor furniture restoration

Professional Deck аnd Furniiture Restoration іn London and Surrey

Professional outdoor furniture restoration, garden furniture cleaning, ɑnd wooden decking pressure

washing services аcross London andd Surrey. Оveг 20 years of experience.

Ϲall 01784 456 475.

Feel free tο surf too my webpage :: Decking cleaning services

2025-02-22下午8:18

It’s a pity you don’t have a donate button! I’d most certainly donate

to this outstanding blog! I guess for now

i’ll settle for bookmarking and adding your RSS feed to my Google account.

I look forward to new updates and will share this blog with my Facebook group.

Chat soon!

Also visit my site SITUS PENIPU

2025-02-23上午2:01

Howdy, i read your blog occasionally and i own a similar one and i was just

wondering if you get a lot of spam remarks? If so how do you

stop it, any plugin or anything you can suggest?

I get so much lately it’s driving me crazy so any assistance is very much appreciated.

Here is my website: SITUS PENIPU

2025-02-23上午7:19

That is a really good tip especially to those fresh to the blogosphere.

Short but very accurate info… Appreciate your sharing this one.

A must read article!

my page :: how early can you apply for japan e-visa

2025-02-23下午4:17

Why visitors still use to read news papers when in this technological globe the whole thing is available on net?

Take a look at my blog: tiktok download 37.5.3

2025-02-24下午12:15

Heya i am for the first time here. I found this board and I

find It really useful & it helped me out a lot. I hope to give something back

and aid others like you aided me.

Stop by my web blog … Why is Auto Glass So Expensive?

2025-02-24下午6:47

At this time I am ready to do my breakfast,

when having my breakfast coming again to read other news.

Also visit my web blog :: apply-tourist-visa-australia-for-parents

2025-02-25上午4:45

This paragraph will assist the internet viewers

for building up new blog or even a blog from start to end.

Have a look at my blog post :: Buy DA 30 Backlinks

2025-02-25下午2:00

We’re a gaggle of volunteers and starting a brand new scheme in our community.

Your website provided us with helpful info to work on. You have done a formidable activity and our entire group can be grateful to you.

My blog post: used ks5 pro

2025-02-26上午1:35

Hello there! I just would like to give you a huge thumbs up for the excellent

information you have here on this post. I will be coming back to

your blog for more soon.

my webpage :: index

2025-02-26上午2:58

Hi i am kavin, its my first occasion to commenting anywhere, when i read this article i thought i could also

create comment due to this good paragraph.

Also visit my web site – PENIPU ONLINE

2025-02-26上午3:36

Hi! I know this is kind of off-topic but I needed

to ask. Does operating a well-established blog like yours require a lot of work?

I’m completely new to running a blog but I do write in my diary everyday.

I’d like to start a blog so I will be able to share my own experience

and views online. Please let me know if you have any kind of suggestions or tips for

brand new aspiring blog owners. Appreciate it!

Here is my web blog; hatay iskenderun escort

2025-02-26上午8:50

This web site definitely has all the information I needed concerning this subject and didn’t know who to ask.

Feel free to surf to my homepage – video mesum anak kecil

2025-02-26下午2:41

hi!,I like your writing very a lot! percentage we keep in touch

more approximately your article on AOL? I require an expert in this area to

resolve my problem. Maybe that is you! Having a look forward to peer you.

Also visit my blog post – situs bokep

2025-02-26下午4:14

Howdy exceptional blog! Does running a blog like this require a large

amount of work? I’ve absolutely no knowledge of programming

but I was hoping to start my own blog in the near future.

Anyway, if you have any recommendations or tips for new blog owners please share.

I know this is off topic but I simply had to ask. Thanks!

My site – psychics.com login

2025-02-26下午8:49

Greetings! Very useful advice within this post!

It is the little changes that make the greatest changes. Thanks for sharing!

My web page: abg indonesia (emutin.wiki)

2025-02-27上午12:07

It’s fantastic that you are getting ideas from this post as well as

from our dialogue made at this time.

Also visit my web page PUG555

2025-02-27上午1:37

Tremendous issues here. I’m very satisfied to see your post.

Thanks so much and I am looking forward to touch you. Will you please

drop me a mail?

Also visit my web-site: elazığ escort

2025-02-27上午8:45

Sweet blog! I found it while browsing on Yahoo News.

Do you have any tips on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get

there! Thank you

Check out my web blog – g2gbet

2025-02-27下午4:36

I visited many sites however the audio feature for audio songs current at this site is really fabulous.

My blog: elliptique

2025-02-27下午5:27

Hello would you mind stating which blog platform you’re working with?

I’m looking to start my own blog in the near future but I’m having

a hard time choosing between BlogEngine/Wordpress/B2evolution and Drupal.

The reason I ask is because your design and style seems different

then most blogs and I’m looking for something unique.

P.S My apologies for being off-topic but I had to ask!

my web site – PENIPU ONLINE

2025-02-28上午2:42

Thanks for sharing your thoughts on Peliou Ground protection mats can use for temporary access

roads|Construction sites HDPE protection mats|Lawn Protection Mats can protect the grass areas|Lawn Protection Mats for agricultural roads of Peliou manufacturer.

Regards

my website The Billionaire Brain Wave reviews

2025-02-28上午6:25

Everyone loves it whenever people get together and share opinions.

Great blog, continue the good work!

Here is my site: Buy 100 Proxies – 100proxies.com –

2025-02-28下午4:05

It’s hard to find educated people for this topic, but you sound like you know

what you’re talking about! Thanks

Check out my page Inexpensive color copies printing for certificates

2025-02-28下午9:21

Greetings from Ohio! I’m bored at work so I decided to check out your blog on my iphone

during lunch break. I really like the information you provide here

and can’t wait to take a look when I get home.

I’m surprised at how quick your blog loaded on my cell phone ..

I’m not even using WIFI, just 3G .. Anyways,

superb blog!

Feel free to visit my homepage: Dreamzy Humidifier reviews

2025-03-01上午2:45

Appreciating the commitment you put into your site and detailed information you provide.

It’s nice to come across a blog every once in a while that isn’t the same outdated rehashed material.

Great read! I’ve bookmarked your site and I’m including

your RSS feeds to my Google account.

Feel free to surf to my web site … black garlick

2025-03-01上午5:00

Hey there, You have done a great job. I’ll certainly

digg it and personally suggest to my friends.

I am sure they’ll be benefited from this website.

Feel free to surf to my web-site – Sight Care reviews

2025-03-01上午8:49

I believe what you posted was very logical. However, what about

this? suppose you wrote a catchier post title? I ain’t

suggesting your content is not good, but suppose you

added a title to possibly get people’s attention? I mean ground protection mats|Lawn Protection Mats – Peliou is

a little boring. You ought to peek at Yahoo’s

home page and see how they create news titles to get viewers to click.

You might add a related video or a pic or two to get people

interested about everything’ve written. Just my opinion,

it might make your posts a little livelier.

Here is my site – Power App Folex

2025-03-01上午11:52

Wonderful beat ! I would like to apprentice at the same

time as you amend your site, how can i subscribe for a weblog

web site? The account helped me a acceptable deal.

I have been a little bit familiar of this your broadcast offered brilliant transparent idea

Feel free to visit my page; best bitcoin casinos

2025-03-01下午6:36

you are truly a just right webmaster. The web site loading speed is amazing.

It sort of feels that you’re doing any distinctive trick.

Furthermore, The contents are masterwork. you’ve performed a magnificent job

on this topic!

Also visit my web-site: sex việt nam gái xinh múp nõn

2025-03-01下午11:19

Have you ever thought about including a little bit more than just

your articles? I mean, what you say is important and all.

Nevertheless just imagine if you added some great graphics or videos

to give your posts more, “pop”! Your content is excellent

but with images and videos, this blog could certainly be one of the most beneficial in its field.

Fantastic blog!

Check out my page sex bao dam tre em

2025-03-02上午12:55

Hello there, I discovered your website by means of Google even as searching for a related matter, your web site got here up,

it appears to be like great. I’ve bookmarked it in my google bookmarks.

Hello there, just become alert to your blog through Google, and found that it is really informative.

I’m going to be careful for brussels. I’ll be grateful if you continue

this in future. Many people can be benefited from your writing.

Cheers!

Here is my web blog :: GreenyTrader

2025-03-02上午12:56

Hi there to every one, the contents existing at this web page are truly awesome for people experience, well,

keep up the good work fellows.

Here is my page penis enlargement

2025-03-02上午1:07

It’s a shame you don’t have a donate button! I’d without a doubt donate to this

superb blog! I suppose for now i’ll settle for book-marking and adding your RSS

feed to my Google account. I look forward to brand new updates and will share this website with my Facebook group.

Talk soon!

Feel free to surf to my website – FitSpresso reviews

2025-03-02下午3:57

Unquestionably believe that which you said. Your favorite reason seemed to be on the net the easiest thing to be aware of.

I say to you, I definitely get irked while people think

about worries that they plainly don’t know about.

You managed to hit the nail upon the top and also defined out the whole thing without having

side-effects , people can take a signal. Will probably be back to get more.

Thanks

Here is my page: PENIPU ONLINE

2025-03-02下午4:23

Every weekend i used to go to see this web page, because i wish for enjoyment, for the

reason that this this web page conations really nice funny stuff too.

Feel free to surf to my web page; situs emakbet terpercaya

2025-03-02下午7:41

Hey! Do you use Twitter? I’d like to follow you if that would be okay.

I’m absolutely enjoying your blog and look forward to new posts.

my webpage – Dreamzy Humidifier reviews

2025-03-02下午8:36

Hi there would you mind letting me know which webhost you’re working with?

I’ve loaded your blog in 3 different browsers and I must say this blog loads a lot quicker then most.

Can you recommend a good hosting provider at a reasonable price?

Thanks a lot, I appreciate it!

Also visit my blog post Cancap

2025-03-02下午9:33

I’ve read several excellent stuff here. Definitely price

bookmarking for revisiting. I wonder how a lot attempt you put

to make one of these wonderful informative web site.

Stop by my homepage; Diet

2025-03-02下午10:18

hello!,I love your writing very so much! percentage we be in contact extra about your post

on AOL? I require an expert on this house to resolve my problem.

May be that is you! Looking forward to see you.

Here is my website … Best Forum Backlinks

2025-03-03下午12:57

What’s up, its fastidious article regarding media print, we all be aware of media is a great source of information.

Also visit my site; Путешествие

2025-03-03下午3:52

Thank you for sharing your thoughts. I really appreciate your efforts and I am waiting for your next post thanks once again.

My blog: 8kbet com

2025-03-03下午5:08

Νаtural Mounjaro Alternative Recipe

Natural Moᥙnjaro Ingredients:

1 cup of hot green tea (rich in antioxidants and helps sρeed up the metabolism).

1 tablespoon of organiс aрple cider vinegar (helps control aрpetite and regulate blood sugar).

1 tеaspoօn turmeric powder (rеduces inflammаtion and promօtes fat burning).

1 teaspoon of pure honey (sweetens naturally and provides sustainable energy).

1 pinch of cayenne pеpper (stimuⅼates metɑbolism and promotes calorie

burning).

Natural Mounjaro Directions:

Prepare the green tea as normal and let it cool for about 2 minutes.

Aԁd the apple cider νinegar, turmeric, honey and

cayenne pepper to the green tea.

Miҳ well until all the ingredients are incorporateɗ.

Drink the mixture sⅼowly, ρreferablʏ in the morning

or before a meal.

Natural Mounjaro Benefits:

Green Tea: C᧐ntaіns cateⅽhins thаt help

burn fat.

Apple ⅽider vinegar: Helps digestion and regulates insulin leveⅼs.

Turmeric: Contains curcumin, a powerfսl anti-inflаmmɑtory and

antioxidant.

Honey: Provides energy and combats sugar cravings.

Cayenne pepper: Increases thermogenesis, helping the body to burn more calories.

Have a look at my blog – website

2025-03-04上午4:16

Remarkable! Its in fact awesome piece of writing, I have

got much clear idea on the topic of from this piece of writing.

Here is my site Immediate AI

2025-03-04上午9:54

Jual Besi Baja Ter murah Kota Medan, Agen Sinar Baja Terpercaya ,

Agen Besi Baja Medan, Distributor Baja Terbaik Medan, Agen Besi Terlengkap

Feel free to surf to my site :: Agen Besi Kota Medan,Distributor Sinar Baja Murah Medan,Jual Besi Baja Terlengkap Kota Medan, Baja

2025-03-04上午10:02

Toko Besi Baja Ter murah Medan, Agen Sinar Baja Murah ,

Agen Besi Baja Terpercaya , Jual Baja Murah Kota Medan, Supplier

Besi Terpercaya

Here is my web site – Pabrik Baja Terpercaya di Kota Medan

2025-03-04上午10:43

I am regular reader, how are you everybody? This post

posted at this site is actually fastidious.

Feel free to surf to my homepage video mesum anak kecil

2025-03-04下午8:15

Hi there, just wanted to say, I liked this article. It was

helpful. Keep on posting!

my site; 7к казино вход

2025-03-04下午9:53

Nice weblog here! Additionally your website loads up very fast!

What host are you the use of? Can I am getting your associate link for your host?

I want my web site loaded up as fast as yours lol

Look into my homepage; african porn

2025-03-04下午10:36

In fact no matter if someone doesn’t know then its up to other visitors that they will assist, so here it

happens.

Also visit my homepage :: hokidewa

2025-03-04下午11:13

I always used to read piece of writing in news papers but now as I am

a user of net so from now I am using net for content,

thanks to web.

Review my webpage … imp source

2025-03-05上午12:10

Hello, i believe that i saw you visited my site so i came to go back the desire?.I am attempting to to

find issues to improve my website!I guess its ok

to make use of some of your ideas!!

Also visit my website – instant withdrawal casino

2025-03-05下午6:37

It’s an amazing piece of writing in favor of all the internet visitors; they will get benefit

from it I am sure.

Also visit my site: e2bet

2025-03-05下午8:17

I am extremely impressed along with your writing abilities as neatly as with the layout for your weblog.

Is this a paid subject or did you customize it

your self? Anyway stay up the excellent quality

writing, it is rare to peer a great blog like this one nowadays..

my web page: Bokep Terbaru

2025-03-06上午2:08

Thanks in support of sharing such a pleasant idea, post is pleasant,

thats why i have read it completely

Visit my site: cheap tyres London

2025-03-06下午4:17

gw3xu0

2025-03-06下午9:47

Hello! This is kind of off topic but I need

some help from an established blog. Is it tough to set up your own blog?

I’m not very techincal but I can figure things out pretty quick.

I’m thinking about setting up my own but I’m not sure where to start.

Do you have any points or suggestions? Thanks

Check out my page; best drugs

2025-03-07上午4:03

If you want to grow your experience simply keep visiting this site and be updated with the most recent news update posted here.

My web blog – video sex viral

2025-03-07下午10:20

Wow that was strange. I just wrote an extremely long comment but

after I clicked submit my comment didn’t show up. Grrrr…

well I’m not writing all that over again. Anyway, just wanted to say great blog!

Look at my web-site … bokep viral

2025-03-08上午4:24

Hello there! I simply want to give you a huge thumbs up

for the great info you have got right here on this post.

I will be coming back to your website for more

soon.

Here is my web site :: mau777

2025-03-08上午9:22

Heya i am for the first time here. I came across this board and I find

It really useful & it helped me out a lot. I hope to give something back

and help others like you helped me.

Have a look at my web-site: Nitric Boost Ultra

2025-03-08下午7:36

I visited several web pages except the audio feature for audio songs present

at this site is truly marvelous.

Feel free to surf to my web page; daftar emakbet

2025-03-10下午1:41

Hi there, its fastidious piece of writing regarding media print, we all be familiar with media is a

wonderful source of information.

Feel free to surf to my web site :: instagram download new version

2025-03-11上午1:57

I am regular reader, how are you everybody? This paragraph posted at this web site

is genuinely pleasant.

Feel free to surf to my page; best drugs

2025-03-11上午2:27

Hey, I think your website might be having browser compatibility issues.

When I look at your blog site in Firefox, it looks fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up! Other then that,

excellent blog!

Feel free to surf to my website BOKEP INDONESIA

2025-03-11上午4:39

always i used to read smaller posts that also clear their motive, and that is also happening with

this article which I am reading here.

Visit my webpage … power balance bracelet

2025-03-11上午8:01

Hello, its pleasant post on the topic of media print, we all know media is a fantastic source

of facts.

My page; agen slot gacor

2025-03-11上午9:40

Incredible points. Outstanding arguments. Keep up the amazing spirit.

Feel free to visit my page … bokep cina premium

2025-03-12上午10:40

May I simply just say what a comfort to find somebody that truly understands what

they are discussing over the internet. You definitely realize how to bring a problem to light and make

it important. More and more people ought to check this out and understand this side of your story.

I was surprised that you’re not more popular given that you most

certainly have the gift.

Also visit my web site … basta online casino

2025-03-12下午2:27

Superb website you have here but I was curious if you knew of any user discussion forums that cover the same topics talked about in this article?

I’d really like to be a part of community where I can get opinions from

other knowledgeable people that share the same interest.

If you have any recommendations, please let me know.

Cheers!

my blog post: viagra

2025-03-12下午6:27

I enjoy reading through an article that will make men and women think.

Also, many thanks for allowing me to comment!

Also visit my homepage :: blue salt trick for men ingredients

2025-03-13上午12:04

Hi, just wanted to say, I enjoyed this post. It was helpful.

Keep on posting!

Also visit my web-site :: making love

2025-03-13上午2:35

Can you tell us more about this? I’d want to find out some additional information.

Also visit my homepage; turnover

2025-03-13上午3:27

I love your blog.. very nice colors & theme.

Did you create this website yourself or did you hire someone to do it for you?

Plz answer back as I’m looking to construct my own blog and would like to know where u got this from.

many thanks

Here is my website sexy car wash hot

2025-03-13上午9:00

magnificent put up, very informative. I wonder why the other experts

of this sector don’t notice this. You should continue your

writing. I am sure, you have a great readers’ base already!

Feel free to surf to my blog … new online casinos

2025-03-14上午7:05

Please let me know if you’re looking for a writer

for your site. You have some really great posts and I feel I would be a good

asset. If you ever want to take some of the load off, I’d love to write some content for your

blog in exchange for a link back to mine. Please blast me an e-mail if interested.

Cheers!

my blog u888

2025-03-14下午1:32

I like the valuable info you provide in your articles.

I will bookmark your blog and check again here regularly.

I am quite sure I’ll learn a lot of new stuff right here!

Good luck for the next!

Feel free to surf to my webpage: Stages of acne

2025-03-15下午12:36

Your style is very unique in comparison to other people I have read stuff

from. Thank you for posting when you’ve got the opportunity, Guess I’ll just book mark this web site.

Feel free to visit my web page – apply visa online

2025-03-15下午1:20

Just desire to say your article is as astounding. The clarity for your submit

is simply cool and i could suppose you’re a professional in this subject.

Fine along with your permission let me to grab your RSS feed to stay

updated with approaching post. Thanks one million and please keep up the enjoyable work.

Here is my blog post; sex bebas

2025-03-15下午5:23

There’s definately a lot to know about this issue.

I love all the points you have made.

my web blog: Bokep Terbaru 2025

2025-03-15下午8:53

I blog frequently and I truly appreciate your content.

The article has truly peaked my interest.

I’m going to book mark your website and keep

checking for new information about once per week. I subscribed to your Feed as

well.

Here is my site – advertise Car sexy

2025-03-15下午10:09

I’m not sure where you are getting your info, but great topic.

I needs to spend some time learning much more or understanding

more. Thanks for wonderful information I was looking for this information for my mission.

Check out my blog post: link

2025-03-16上午10:36

I’m impressed, I have to admit. Seldom do I encounter a blog that’s both equally educative and engaging,

and without a doubt, you’ve hit the nail on the

head. The issue is something that too few people are speaking intelligently about.

I am very happy I stumbled across this in my hunt for something regarding this.

My web page: Patrycja Wenczyńska Ladacznica

2025-03-17上午2:35

bookmarked!!, I love your website!

My web-site daftar mau777

2025-03-17上午10:10

My brother suggested I might like this website. He was once totally right.

This publish truly made my day. You can not imagine just how much time I had spent for this information!

Thanks!

Here is my web page … Bokep Terbaru Indonesia

2025-03-17下午1:30

Write more, thats all I have to say. Literally, it seems as though you

relied on the video to make your point. You clearly know

what youre talking about, why throw away your intelligence

on just posting videos to your blog when you could be giving us something informative to read?

Also visit my page – best email marketing tools

2025-03-18上午12:55

Hey there! I’m at work browsing your blog from my new apple iphone!

Just wanted to say I love reading through your blog and look forward to all your posts!

Keep up the outstanding work!

Review my web page … ice water hack

2025-03-18上午1:58

It’s really a cool and useful piece of information. I’m happy that you just shared this helpful info with us.

Please keep us up to date like this. Thanks for sharing.

Feel free to visit my homepage touristrequirements.info

2025-03-18上午5:24

Thankfulness to my father who shared with me concerning this website, this web site

is in fact remarkable.

Feel free to visit my blog post: Veil Syndrax

2025-03-18上午7:54

At this moment I am ready to do my breakfast, when having my breakfast coming again to read more news.

My website: ice water hack

2025-03-18下午2:34

I do not know whether it’s just me or if perhaps everybody else encountering problems with your blog.

It appears like some of the written text on your posts are running off the screen. Can someone else please comment and let me know if

this is happening to them as well? This might be a problem with my internet browser because I’ve

had this happen previously. Thank you

Here is my page … best porn

2025-03-19上午1:51

Greetings! I’ve been following your website for a while now and finally got the courage to go ahead and give you a shout out from Dallas Tx!

Just wanted to say keep up the excellent job!

Look at my homepage – Акне на спине

2025-03-19上午3:54

Excellent post. I was checking continuously this blog

and I am impressed! Very useful info specially the last part :

) I care for such info much. I was looking for this certain info for a very long

time. Thank you and best of luck.

Take a look at my page :: lotto champ reviews

2025-03-19上午7:28

Now I am ready to do my breakfast, afterward having my breakfast coming yet again to read further news.

Here is my page: new online casinos

2025-03-19上午8:09

I loved as much as you’ll receive carried out right here.

The sketch is tasteful, your authored material stylish. nonetheless,

you command get got an impatience over that you wish be delivering the following.

unwell unquestionably come more formerly again as

exactly the same nearly very often inside case you shield this increase.

my site … honey1.testedhoneypot.com

2025-03-19上午10:09

Excellent post. I was checking continuously this blog and I’m impressed!

Extremely helpful information specially the last part 🙂 I care for such info

much. I was looking for this particular info for a long time.

Thank you and good luck.

Check out my blog – fm88

2025-03-19下午6:29

Incredible points. Sound arguments. Keep up the great

spirit.

Here is my site :: vach ngan ve sinh

2025-03-19下午7:16

Good day! Would you mind if I share your blog with my myspace group?

There’s a lot of people that I think would really enjoy your content.

Please let me know. Many thanks

Feel free to surf to my blog :: visit here

2025-03-20上午8:12

At this time it sounds like Movable Type is the top blogging

platform out there right now. (from what I’ve read) Is

that what you’re using on your blog?

My webpage :: touristrequirements.info

2025-03-20上午11:18

Hello, I believe your website might be having

browser compatibility issues. When I take a look at your website in Safari,

it looks fine however, if opening in IE, it’s got some overlapping issues.

I merely wanted to provide you with a quick heads up!

Other than that, excellent website!

Here is my site; Buy Premium Backlinks

2025-03-20上午11:23

Thanks for finally writing about > ground protection mats|Lawn Protection Mats – Peliou win88.cash

2025-03-20下午4:57

Hey very cool site!! Guy .. Excellent .. Superb .. I will

bookmark your blog and take the feeds also?

I am happy to search out a lot of useful info here within the publish, we want work out more techniques in this regard,

thanks for sharing. . . . . .

Also visit my blog post – PENIPUAN !!!

2025-03-20下午7:09

Thanks for sharing your thoughts on Peliou Ground protection mats can use for temporary

access roads|Construction sites HDPE protection mats|Lawn Protection Mats can protect the grass areas|Lawn Protection Mats for agricultural roads of Peliou

manufacturer. Regards

My web site; memek basah

2025-03-20下午8:07

Wow that was strange. I just wrote an very long comment but after I

clicked submit my comment didn’t appear. Grrrr…

well I’m not writing all that over again. Anyway, just wanted

to say great blog!

Here is my web page :: youtube channel open tamil

2025-03-20下午9:12

Very good info. Lucky me I recently found your site by chance (stumbleupon).

I’ve book marked it for later!

Here is my website: PENIPUAN !!!

2025-03-21上午2:31

Appreciating the hard work you put into your site and in depth information you

offer. It’s awesome to come across a blog every once in a while that isn’t the same unwanted rehashed information. Fantastic read!

I’ve bookmarked your site and I’m adding your RSS feeds to my

Google account.

Here is my website: touristrequirements.info

2025-03-21上午9:48

I love your blog.. very nice colors & theme. Did you design this website yourself or did you

hire someone to do it for you? Plz answer back as I’m looking to construct my own blog and would like to know where u got this from.

thanks

Here is my blog post sbobetมือถือ

2025-03-21上午10:03

reparación de maquinaria agrícola

Dispositivos de ajuste: importante para el operación fluido y óptimo de las máquinas.

En el entorno de la avances actual, donde la efectividad y la estabilidad del dispositivo son de máxima significancia, los sistemas de ajuste juegan un papel vital. Estos dispositivos especializados están desarrollados para calibrar y asegurar partes móviles, ya sea en equipamiento productiva, vehículos de movilidad o incluso en equipos domésticos.

Para los especialistas en conservación de equipos y los ingenieros, operar con equipos de balanceo es fundamental para garantizar el rendimiento fluido y seguro de cualquier aparato giratorio. Gracias a estas herramientas innovadoras avanzadas, es posible reducir significativamente las oscilaciones, el zumbido y la presión sobre los rodamientos, aumentando la longevidad de partes costosos.

De igual manera relevante es el rol que cumplen los aparatos de calibración en la soporte al usuario. El ayuda experto y el conservación constante utilizando estos aparatos habilitan dar asistencias de óptima excelencia, aumentando la contento de los compradores.

Para los propietarios de proyectos, la aporte en estaciones de ajuste y dispositivos puede ser clave para aumentar la productividad y rendimiento de sus equipos. Esto es sobre todo trascendental para los empresarios que administran pequeñas y intermedias empresas, donde cada elemento importa.

Asimismo, los sistemas de calibración tienen una gran uso en el área de la seguridad y el monitoreo de excelencia. Habilitan encontrar probables problemas, previniendo intervenciones caras y daños a los aparatos. Además, los resultados generados de estos sistemas pueden utilizarse para mejorar procesos y mejorar la reconocimiento en buscadores de exploración.

Las áreas de uso de los dispositivos de ajuste comprenden numerosas áreas, desde la producción de transporte personal hasta el seguimiento ambiental. No interesa si se habla de importantes elaboraciones industriales o limitados establecimientos domésticos, los dispositivos de balanceo son esenciales para promover un rendimiento productivo y sin presencia de interrupciones.

2025-03-21上午11:48

Greetings! Quick question that’s totally off topic.

Do you know how to make your site mobile friendly? My website looks weird

when viewing from my iphone. I’m trying to find a template or plugin that might be able

to fix this problem. If you have any recommendations, please share.

Cheers!

Look at my site – tấm compact

2025-03-21下午4:47

Howdy! I simply want to offer you a big thumbs up for

your great info you have here on this post.

I am returning to your web site for more soon.

My website: 69VN

2025-03-21下午7:23

Thanks for finally writing about > ground protection mats|Lawn Protection Mats – Peliou

keonhacaibet88

2025-03-22上午1:01

Every weekend i used to go to see this website, as i want enjoyment,

as this this web page conations in fact nice funny information too.

my web page :: Profit Edge

2025-03-22上午3:49

Ahaa, its nice conversation on the topic of this

piece of writing here at this webpage, I have read all

that, so at this time me also commenting here.

Here is my homepage – https://alpinesidingpros.com/

2025-03-22上午9:40

I am sure this paragraph has touched all the internet visitors, its really

really nice paragraph on building up new webpage.

Feel free to visit my website hubet – beyondstorage.io

–

2025-03-22下午9:15

Hello, I think your website might be having browser compatibility issues.

When I look at your blog site in Firefox, it looks

fine but when opening in Internet Explorer, it has some overlapping.

I just wanted to give you a quick heads up! Other then that, very

good blog!

Feel free to surf to my webpage: touristrequirements.info

2025-03-23上午2:07

I needed to thank you for this wonderful read!! I absolutely enjoyed every little bit of it.

I have you saved as a favorite to check out new stuff you post…

Have a look at my web page: Immediate Lispro

2025-03-23上午5:12

Hey there great blog! Does running a blog similar to this require a lot of work?

I’ve no knowledge of programming but I was hoping to start

my own blog soon. Anyways, should you have any recommendations or techniques for new blog owners please share.

I understand this is off subject nevertheless I simply wanted to

ask. Thank you!

my blog: แทงบอลผ่านเว็บ SBOBET

2025-03-23下午1:00

I’m amazed, I have to admit. Rarely do I encounter a blog that’s equally educative and

entertaining, and without a doubt, you’ve hit the nail on the head.

The issue is something which not enough folks are speaking

intelligently about. Now i’m very happy I came across this in my search for something regarding this.

Here is my blog post best online casinos australia

2025-03-23下午1:15

At this time it seems like Expression Engine is the top blogging platform

available right now. (from what I’ve read) Is that what you’re using on your blog?

Feel free to visit my website; raffi777

2025-03-23下午5:37

I just like the helpful info you supply in your articles. I’ll bookmark your weblog and take a look at once more here frequently.

I’m quite certain I’ll be told many new stuff proper here!

Good luck for the following!

Feel free to surf to my page – SITUS PENIPU

2025-03-24上午12:30

Great weblog right here! Additionally your website a lot up very fast!

What host are you the usage of? Can I am getting your associate link on your

host? I desire my website loaded up as fast as yours lol

Stop by my site :: SITUS PENIPU

2025-03-24上午5:28

It’s very straightforward to find out any topic on web as compared to textbooks, as

I found this article at this web site.

My site – بهترین روتین پوست چرب تا مختلط مستعد جوش ۱۴۰۴

2025-03-24上午9:40

I like the valuable information you provide in your articles.

I’ll bookmark your blog and check again here regularly.

I am quite certain I will learn lots of new stuff right here!

Good luck for the next!

My homepage … Vortex Momentum

2025-03-24下午3:07

Hi there colleagues, its impressive post regarding educationand fully explained, keep it up all the

time.

my site :: best online casinos australia

2025-03-24下午6:26

hello!,I like your writing so so much! proportion we

keep in touch more about your post on AOL?

I need an expert on this house to resolve

my problem. Maybe that is you! Taking a look ahead to

see you.

Also visit my web blog: Dreamers Relief Pillow reviews

2025-03-25上午3:05

I seriously love your website.. Great colors & theme. Did you

develop this site yourself? Please reply back as I’m hoping to create my own website and would like to find out where you got

this from or what the theme is named. Cheers!

Also visit my web page; esta usa visa

2025-03-26下午6:38

Heya i’m for the first time here. I came across this board and I to

find It really useful & it helped me out much. I am hoping

to give one thing back and aid others like you aided me.

My webpage: mitolyn reviews and complaints

2025-03-26下午9:31

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

2025-03-26下午9:48

You actually make it seem so easy with your presentation but I find this matter to be really something which I think I would never understand.

It seems too complicated and very broad for me. I’m looking forward for your next post, I will try to get

the hang of it!

Take a look at my website pembesar penis

2025-03-26下午11:30

My family members all the time say that I am killing my time here at net,

however I know I am getting know-how every day

by reading thes good articles or reviews.

Feel free to surf to my web page :: PENIPU ONLINE

2025-03-27上午3:41

My programmer is trying to convince me to move to .net from PHP.

I have always disliked the idea because of the costs.

But he’s tryiong none the less. I’ve been using WordPress on a

variety of websites for about a year and am anxious about switching to another platform.

I have heard excellent things about blogengine.net.

Is there a way I can import all my wordpress content into it?

Any help would be really appreciated!

My blog post :: Nagano Tonic reviews

2025-03-27上午8:53

Hi there! This blog post couldn’t be written any better!

Reading through this article reminds me of my previous roommate!

He constantly kept preaching about this. I am going to send

this article to him. Fairly certain he’ll have a good

read. I appreciate you for sharing!

My blog post; Republic day speech in english ideas and samples

2025-03-27下午12:12

Fabulous, what a web site it is! This webpage presents valuable information to us, keep it up.

my blog: sex việt nam gái xinh múp nõn

2025-03-27下午2:29

Great post. I was checking constantly this blog and I’m inspired!

Extremely helpful info particularly the last section 🙂 I maintain such info a lot.

I was seeking this certain information for a long time.

Thank you and good luck.

Feel free to visit my web blog best bitcoin casinos

2025-03-27下午8:19

It’s in fact very difficult in this busy life to listen news on Television, thus I only use

world wide web for that purpose, and get the most recent information.

My site :: indian porn

2025-03-28上午11:08

Hmm it looks like your blog ate my first comment (it was extremely long)

so I guess I’ll just sum it up what I wrote

and say, I’m thoroughly enjoying your blog.

I as well am an aspiring blog blogger but I’m still new to

everything. Do you have any points for first-time blog writers?

I’d definitely appreciate it.

Also visit my blog post – my website

2025-03-29上午12:15

Hi! Would you mind if I share your blog with my twitter group?

There’s a lot of people that I think would really appreciate your content.

Please let me know. Thanks

Also visit my webpage: additional reading

2025-03-29下午5:42

Your style is unique in comparison to other folks

I’ve read stuff from. Thanks for posting when you’ve got the

opportunity, Guess I’ll just bookmark this site.

my webpage dul prn

2025-03-29下午11:28

Hi, I do believe this is a great web site. I stumbledupon it 😉 I’m

going to return yet again since i have bookmarked

it. Money and freedom is the greatest way to change, may you be rich and continue to help other people.

Have a look at my webpage: Situs Penipu

2025-03-31上午12:21

70918248

References:

Signs Of Steroid Use In Females – Iflirt.App,

2025-03-31下午12:09

I think this is among the most vital info for me.

And i am happy studying your article. But should statement

on some basic things, The site style is ideal,

the articles is actually great : D. Good process, cheers

Also visit my web-site: Потоотделение

2025-03-31下午10:28

70918248

References:

Closest legal thing To Steroids

2025-04-01上午3:23

Undeniably believe that which you stated. Your favorite justification seemed to be on the internet the easiest thing to be aware of.

I say to you, I certainly get annoyed while people think

about worries that they just do not know about.

You managed to hit the nail upon the top as well as defined out

the whole thing without having side-effects ,

people can take a signal. Will likely be back to get more.

Thanks

my web blog :: décoratrice d’intérieur Toulouse

2025-04-02上午3:53

I read this post fully about the comparison of newest and earlier

technologies, it’s remarkable article.

Look at my blog post – decoratrice d’interieur Toulouse

2025-04-02上午9:30

At this time I am going away to do my breakfast, later than having

my breakfast coming yet again to read further news.

Here is my homepage: link

2025-04-02下午4:19

I all the time used to study post in news papers but now as I am a user of net so from now I am using net for posts, thanks to web.

My web blog; https://hectoresgr65320.blogoscience.com/40415785/promote-your-business-with-free-online-advertising

2025-04-02下午5:28

Hi, I would like to subscribe for this blog to

obtain most recent updates, thus where can i do it please help

out.

Feel free to surf to my web-site – おすすめのオンカジBEST3

2025-04-02下午7:44

This site was… how do I say it? Relevant!!

Finally I’ve found something that helped me.

Thanks a lot!

Review my page: Teds Woodworking reviews

2025-04-02下午7:53

Ahaa, its good conversation on the topic of this article here at this website,

I have read all that, so now me also commenting here.

Here is my blog: Cold War Generator reviews

2025-04-02下午11:11

Howdy would you mind sharing which blog platform you’re using?

I’m looking to start my own blog in the near future but I’m having a difficult time selecting between BlogEngine/Wordpress/B2evolution and

Drupal. The reason I ask is because your design seems different then most

blogs and I’m looking for something unique. P.S Sorry for being off-topic but I had to ask!

My blog post … bdsmcommunityhub.net

2025-04-03上午1:26

We are a bunch of volunteers and opening a brand new scheme in our community.

Your site provided us with useful info to work

on. You have performed an impressive process and our whole group will likely be grateful to you.

Check out my blog :: オンカジで借金地獄

2025-04-03上午3:59

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

2025-04-03下午5:53

Hi, this weekend is fastidious in favor of me, because this moment i am reading this

fantastic educational post here at my residence.

Here is my web blog … website

2025-04-03下午10:27

I’ve been exploring for a little for any high-quality articles or blog

posts in this kind of area . Exploring in Yahoo I at last stumbled upon this website.

Studying this information So i am satisfied to show that

I’ve a very good uncanny feeling I came upon just what I needed.

I most no doubt will make sure to do not overlook this website and provides it a glance on a relentless basis.

My web page: faq омоложение кожи

2025-04-04上午12:05

Woah! I’m really loving the template/theme of this website.

It’s simple, yet effective. A lot of times it’s very

difficult to get that “perfect balance” between superb usability

and visual appearance. I must say that you’ve done a fantastic job with this.

Also, the blog loads extremely fast for me on Firefox.

Excellent Blog!

Here is my web blog; persona

2025-04-04上午3:41

I absolutely love your blog and find many of your post’s to be precisely what I’m looking for.

Do you offer guest writers to write content in your case? I wouldn’t mind

publishing a post or elaborating on many of the subjects you write about here.

Again, awesome weblog!

My web blog: Вакуумная чистка лица

2025-04-04上午7:32

70918248

References:

mass Steroid cycle

2025-04-04下午3:42

With havin so much written content do you ever run into any issues of

plagorism or copyright infringement? My blog has a lot of completely

unique content I’ve either authored myself or outsourced but it looks like a lot of it is popping

it up all over the internet without my agreement. Do you know any ways to help reduce content from being stolen? I’d genuinely appreciate it.

my web-site; best online casinos australia

2025-04-04下午11:55

Good post. I learn something totally new and challenging on sites I stumbleupon everyday.

It’s always exciting to read articles from other authors

and use a little something from their web sites.

My web site: situs game online populer

2025-04-05上午1:14

Admiring the dedication you put into your blog and in depth information you

offer. It’s good to come across a blog every once in a

while that isn’t the same old rehashed information. Excellent read!

I’ve saved your site and I’m including your RSS feeds to my Google

account.

Here is my homepage – click resources

2025-04-05上午2:58