Ground mats for construction

1552ground mats for construction

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

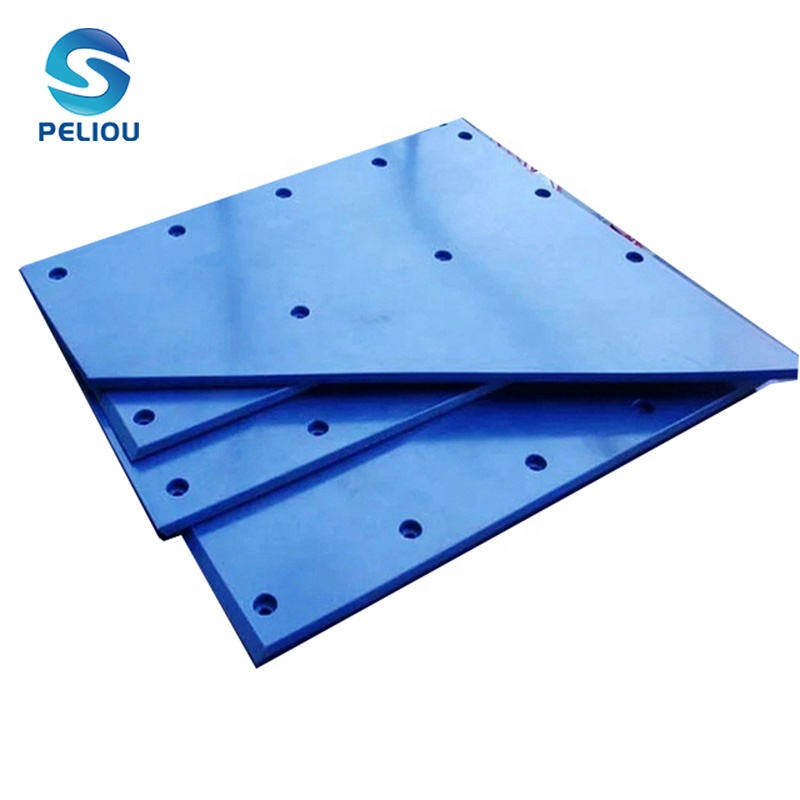

The polymer coal bunker liner not only has the characteristics of increasing slip, but also has the characteristics of wear resistance and buffering. After years of careful research on coal blockage in the coal bunker by our company, we have found that a non adhesive material is designed and installed on the surface of the coal hopper as the liner, making the coal flow smoothly and easily through the funnel. And it also protects the moisture in the coal from rusting the coal hopper, alleviates the impact of coal falling from a height on the coal hopper, and prolongs the service life of the coal hopper. Saves maintenance and dredging time, avoiding unnecessary downtime for repairs. Indirectly creating benefits for manufacturers.

In previous articles, we have summarized and introduced the knowledge of coal bunker lining boards, and now we will summarize some issues that need to be paid attention to during their initial use:

1. Temperature control: It uses ambient temperature, generally not exceeding 80 ℃. When the temperature is low, please pay attention to the static time of the material in the warehouse to avoid the formation of frozen blocks.

2. Remember not to use external forces to damage its structure or loosen fasteners at will.

3. A special reminder is that the static time of materials in the warehouse should not exceed 36 hours (for sticky materials, please do not stay in the warehouse to prevent clumping). Materials with a moisture content less than 4% can have their static time extended appropriately.

We have introduced the installation method of coal bunker lining plates in previous articles. Today, we will introduce the issues that should be paid attention to during installation based on different thicknesses. Firstly, for coal bunker lining plates with a thickness less than 20mm, users can install the longest side of the lining plate vertically and overlap it. Then it is important to understand that for coal bunker lining plates with a thickness greater than 20mm, we should use a 45 degree overlap with the edge cut. Finally, we would like to remind everyone that the above introductions are all related to their weight, in order to better prevent the liner from slipping. Our users should also pay attention to tightening the installed screws when maintaining the lining board. Once any looseness is found, we should tighten it in a timely manner to prevent the lining board from slipping.

MC nylon rods are widely used in machinery, chemical, food processing and other industries, and are favored by consumers for their excellent wear resistance and mechanical properties. However, due...

View details

Your article helped me a lot, is there any more related content? Thanks!

2025-01-07下午4:08

Today, I went to the beach with my children. I found a sea shell and gave it to my

4 year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to

her ear and screamed. There was a hermit crab inside and it

pinched her ear. She never wants to go back! LoL I know this is completely off topic but I had to tell

someone!

Here is my blog post … keytamin

2025-02-04下午7:04

It’s really a great and useful piece of information. I’m satisfied that

you simply shared this helpful info with us. Please keep us

informed like this. Thanks for sharing.

Review my webpage; chữ mica

2025-02-05下午9:05

Hey there! Someone in my Facebook group shared this site

with us so I came to look it over. I’m definitely loving the information. I’m bookmarking

and will be tweeting this to my followers! Terrific

blog and terrific design.

Also visit my web-site: leon pulsa

2025-02-06下午8:37

My brother suggested I might like this website. He was

totally right. This post actually made my day. You cann’t imagine simply how much time I

had spent for this information! Thanks!

My blog post; Mech Arena cheats a-coins

2025-02-15下午1:09

Great website you have here but I was wanting to know if

you knew of any community forums that cover the same

topics discussed here? I’d really love to be a part of online community where I can get feedback from other knowledgeable individuals that share the same interest.

If you have any recommendations, please let me know.

Thanks a lot!

Take a look at my web page – fundwise affiliate

2025-02-15下午5:31

Hi, Neat post. There is an issue together with your website in web explorer, might check this?

IE nonetheless is the marketplace chief and a good portion of people

will omit your magnificent writing because of this problem.

my web site … guru traffic

2025-02-16上午11:50

Amazing issues here. I am very satisfied to see your post.

Thank you so much and I am having a look ahead to touch you.

Will you please drop me a mail?

Here is my site :: spam ua

2025-02-18下午2:55

Your method of explaining the whole thing in this post is in fact pleasant, every one be

able to easily understand it, Thanks a lot.

Here is my homepage: instagram download live video

2025-02-19下午1:37

It’s a shame you don’t have a donate button! I’d definitely donate to

this fantastic blog! I guess for now i’ll settle for bookmarking and adding your RSS feed to my Google account.

I look forward to brand new updates and will talk about this

website with my Facebook group. Chat soon!

Stop by my web blog: tolol kau

2025-02-22下午8:43

Wow, that’s what I was exploring for, what a stuff! existing here at this web site,

thanks admin of this web page.

Feel free to visit my website – PENIPU ONLINE

2025-02-26上午8:35

Hi, I wish for to subscribe for this weblog to

obtain newest updates, thus where can i do it please help

out.

my web site: escort elazığ

2025-02-27上午6:17

Wow that was odd. I just wrote an extremely long comment but after I clicked submit my comment didn’t appear.

Grrrr… well I’m not writing all that over again. Anyhow, just wanted

to say wonderful blog!

Visit my web blog :: PENIPU ONLINE

2025-03-02下午3:13

Cool blog! Is your theme custom made or did you download it from somewhere?

A design like yours with a few simple tweeks would really make my blog stand out.

Please let me know where you got your design. Bless you

Here is my web blog: best crypto casinos

2025-03-04上午1:48

I got this website from my friend who shared with me on the topic of this website and now

this time I am browsing this web page and reading very informative posts at this time.

Here is my website – بهترین سایت شرط بندی فوتبال

2025-03-04上午6:33

Hi there, I discovered your blog by means of Google even as looking for a comparable subject, your web

site came up, it appears good. I have bookmarked it

in my google bookmarks.

Hi there, just was alert to your blog through Google,

and located that it is truly informative. I am gonna be

careful for brussels. I will appreciate when you continue this in future.

Many other people will likely be benefited out of your writing.

Cheers!

Look at my page – solar water heater

2025-03-04下午3:23

If some one desires to be updated with newest technologies then he must be visit this web page and be up to date daily.

Also visit my blog post: máy hút bụi công nghiệp

2025-03-04下午10:10

Yesterday, while I was at work, my cousin stole my iPad and tested to see if it can survive a 40

foot drop, just so she can be a youtube sensation. My apple ipad is

now broken and she has 83 views. I know this is totally

off topic but I had to share it with someone!

my site :: کلاس ارز دیجتیال مشهد

2025-03-05上午5:32

g2g168f

Attractive section of content. I just stumbled upon your weblog

and in accession capital to assert that I get actually

enjoyed account your blog posts. Anyway I will be subscribing to your feeds and even I achievement you access consistently fast.

My page – superpg1688

2025-03-05下午11:29

My brother suggested I might like this website. He was entirely right.

This post actually made my day. You can not imagine just how much time I had

spent for this information! Thanks!

Feel free to visit my blog; سایت شرط بندی با واریز مستقیم

2025-03-06下午4:03

Thank you for another informative website. The place else may I get that type of info written in such an ideal

method? I’ve a undertaking that I am simply now running on, and I have been at the look out

for such info.

my blog post … bokep anal

2025-03-07下午11:07

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

2025-03-09上午1:32

I am regular reader, how are you everybody? This article posted at

this web page is truly fastidious.

Here is my blog – BOKEP TERBARU 2025

2025-03-12下午10:22

After exploring a number of the blog articles on your website, I really

appreciate your way of blogging. I added it to my bookmark webpage list and

will be checking back soon. Take a look at my website too and let me know what you think.

My web blog :: my link

2025-03-13下午9:14

I like the helpful information you supply for your articles.

I will bookmark your weblog and take a look at again right here frequently.

I’m quite sure I will be informed many new stuff right here!

Best of luck for the following!

My site; bokep chindo erbaru

2025-03-15上午2:07

I loved as much as you will receive carried out right here.

The sketch is tasteful, your authored subject matter stylish.

nonetheless, you command get got an nervousness over

that you wish be delivering the following. unwell unquestionably come more formerly again since exactly the same nearly

very often inside case you shield this hike.

My web blog: esta-usa

2025-03-16下午10:50

I think this is among the most significant information for me.

And i’m glad reading your article. But want to

remark on some general things, The web site style is ideal, the articles

is really nice : D. Good job, cheers

My website Discover More Here

2025-03-21上午7:23

My partner and I stumbled over here from a different web address

and thought I might check things out. I like what I see so now i am following

you. Look forward to looking at your web page for a second time.

Stop by my homepage … kontol besar

2025-03-22上午4:13

Hello, i think that i saw you visited my web site

so i came to “return the favor”.I am attempting to find things to

enhance my web site!I suppose its ok to use a few of your ideas!!

Feel free to visit my blog; Fit After 50 reviews

2025-03-22上午10:33

Just want to say your article is as amazing. The clearness on your put up is simply excellent and i could assume you are an expert on this subject.

Well together with your permission let me to take hold of your feed

to stay updated with imminent post. Thank you a million and please carry

on the rewarding work.

Feel free to surf to my site … lode88

2025-03-24上午2:30

Great post but I was wondering if you could write a litte more on this topic?

I’d be very thankful if you could elaborate a little

bit more. Cheers!

Also visit my web page … purple peel weight loss

2025-03-26上午10:38

I’m extremely impressed with your writing skills and also with the layout on your weblog.

Is this a paid theme or did you modify it yourself? Anyway

keep up the nice quality writing, it is

rare to see a great blog like this one these days.

Look into my web site – click resources

2025-03-27上午12:38

Hi, I do think this is a great website. I

stumbledupon it 😉 I may return yet again since

i have saved as a favorite it. Money and freedom is the best way to

change, may you be rich and continue to help other people.

Here is my blog post … دانلود مستقیم اپلیکیشن پین باهیس

2025-03-27上午11:17

Asking questions are in fact fastidious thing if

you are not understanding anything completely, but this article provides nice

understanding even.

Feel free to visit my page: PENIPU ONLINE

2025-03-27下午3:41

It’s in fact very complicated in this busy life to listen news on Television, so I simply

use internet for that purpose, and take the most up-to-date information.

My web-site … ANTRI777

2025-03-27下午10:30

Heya! I just wanted to ask if you ever have any problems with hackers?

My last blog (wordpress) was hacked and I ended up losing months

of hard work due to no backup. Do you have any methods to prevent hackers?

my web site … türk ifşa

2025-03-28上午4:49

An impressive share! I have just forwarded this onto a friend who has been conducting a little homework on this.

And he in fact ordered me lunch because I stumbled upon it for him…

lol. So allow me to reword this…. Thanks for the meal!!

But yeah, thanks for spending some time to talk about this subject here on your website.

Also visit my page :: esta usa visa

2025-03-28上午11:52

70918248

References:

legal and safe steroids [compass-framework.com]

2025-03-31上午5:55

Hi there friends, its fantastic article regarding tutoringand entirely defined,

keep it up all the time.

Here is my web-site: https://www.anddownthestretchtheycome.com/users/treasuremon

2025-03-31下午2:02

70918248

References:

which of the following is least likely to be caused by abuse of anabolic Steroids?

2025-04-01上午2:43

It’s remarkable to pay a quick visit this web page and reading

the views of all colleagues regarding this paragraph, while I am also eager of getting

familiarity.

Also visit my site :: محصولات آردن

2025-04-02下午1:03

I have been exploring for a little for any high quality articles or weblog posts in this sort of house .

Exploring in Yahoo I ultimately stumbled

upon this website. Reading this information So

i’m happy to show that I’ve a very excellent uncanny feeling I discovered exactly what I needed.

I such a lot definitely will make certain to don?t put out of your mind this

website and give it a look on a constant basis.

Here is my blog rút tiền 98win

2025-04-03下午5:07

70918248

References:

Anabolic Performance – https://Www.Soundofrecovery.Org/Darlenesavage,

2025-04-04上午12:56

70918248

References:

What Steroids Should I Take To Get Ripped (https://Play.Osurx.Com/)

2025-04-04下午3:48

70918248

References:

what is a steriod

2025-04-05下午3:53

70918248

References:

first time steroid cycle – kupfersulfid.de –

2025-04-05下午9:25

70918248

References:

Anabolic Steroid Online Shop

2025-04-05下午11:08

70918248

References:

how to buy legal steroids (https://Music.growverse.net/)

2025-04-05下午11:11

70918248

References:

Pharmaceutical grade steroids For sale

2025-04-05下午11:12

70918248

References:

Best Anabolic Steroids For Muscle Mass (https://Kayesbamusic.Com/Zaavan4441025)

2025-04-06下午5:26

Anavar helps enhance nitrogen retention in muscular tissues, a important part of maintaining an anabolic

state. By increasing nitrogen retention, Anavar helps an surroundings favorable to

muscle progress and restore, particularly helpful

throughout intense coaching intervals where restoration is important.

When it comes to using Anavar, it may be very important perceive the potential

unwanted facet effects and security issues that come with using this steroid.

Whereas Anavar is considered to be one of the safest anabolic steroids in the

marketplace, it’s nonetheless essential to concentrate on the risks

concerned. Whereas Anavar is taken into account a mild steroid, it nonetheless carries the risk of unwanted effects.

Some common unwanted effects for each women and men embody acne, hair loss, and mood modifications.

More severe dangers can contain liver toxicity, cardiovascular strain,

and hormonal imbalances. Correct monitoring, dosage administration, and regular health

check-ups are crucial to attenuate these dangers. Typically, there’s not

a lot change within the muscle measurement and energy features after you stop taking

Anavar. As far as fat loss is worried, the results are also permanent however you must

remain disciplined with each your diet and training so as to keep results.

If you come off Anavar and start eating junk meals, the outcomes with obviously diminish.

Results can differ based on components such as genetics, food plan, coaching regimen, and dosage.

It’s crucial to method Anavar with responsibility, adhere to beneficial guidelines,

and search professional advice to make sure a protected and effective journey.

Anavar helps in preventing the breakdown of proteins in the physique, which promotes muscle growth and

aids in recovery after workouts. As you embark upon your health expedition with this stack,

bear in mind the significance of adhering to individualized tips.

Appropriate dosage, well-crafted cycles, and

sincere dedication to a healthy life-style are essential to garnering optimum outcomes.

Upholding these rules will set the stage for superior outcomes, and pave a dependable path in course of attaining

your envisioned aspirations. Men aiming for enhanced physique and efficiency commonly uncover that a day by day dosage

ranging from 20 to 100 mg proves highly effective over a interval

of 6 to 12 weeks.

Anavar is massively popular with female users, however girls do

not require the type of post-cycle therapy that males do

after an Anavar cycle. Solely run this cycle if you’ve used

Tren before and understand the means to deal with

its unwanted effects. Though it’s an injectable steroid, Tren is known to be extra

liver-toxic than Anavar, so we keep this as a short cycle.

One Other Anavar stack for men is a pure slicing

cycle and includes one other cutting-specialist steroid in Winstrol.

Winstrol is one of the best chopping compounds obtainable,

and when combined with Anavar, it proves to

be a potent duo for ultimate shredding.

Thus, bodybuilders commonly slowly enhance the dose every few days until attaining a

maximum dose. Regardless Of a modest dose, we find Winstrol continues to produce vital anabolism and fats loss as a end result of potency of

the compound. Consuming higher doses than these specified on this cycle

considerably will increase the chance of side effects without yielding any notable further ends in our expertise.

In a nutshell, Anavar, a slicing or weight reduction aid, is a potent, enticing possibility with its challenges and hurdles.

Effectiveness heavily leans on the user’s dedicated and disciplined lifestyle adjustments,

addressing the necessity for wise usage and at all times putting well being on the forefront.

One of the issues I would like to spotlight right here is that Anavar can result in extreme pumps which

may be painful at occasions, especially within the lower back.

This is an issue that lots of guys experience doing deadlifts whereas on Anavar.

The solely method to recover from this problem is to allow extra rest

in between the sets. Because Anavar is a steroid that is usually well-tolerated by males, your level of

expertise won’t play a big impact in selecting how a

lot Anavar you must take.

Drugs similar to finasteride can be utilized to significantly cut back

DHT ranges within the physique, lowering hair loss.

Nonetheless, this will result in decreased muscle gains, as

DHT is a very anabolic hormone. Anavar does spike dihydrotestosterone (DHT) levels which may contribute to pimples and hair loss.

The cause why pimples can happen on Anavar is as a result of DHT triggers the androgenic receptors in your pores and skin leading to elevated sebum manufacturing and body hair

while suppressing hair growth on your head.

Anavar’s probably the greatest steroids for maintaining your pure testosterone levels as excessive as potential after a cycle.

Therefore, if women and men wish to obtain a small/tight waist, Anavar is a shrewd choice.

As a results of the truth that Anavar does not aromatize, all of that weight

gain will be lean, water-free muscle tissue. Nonetheless, it’s essential to do not forget that every person responds in a different way to

Anavar. The results skilled over the four week cycle can differ

tremendously, with components such as dosage, food plan, and exercise routine playing a pivotal position. It’s

essential to start with a smaller dosage to see how the

body responds, especially for newbies. If you’re contemplating utilizing Oxandrolone, you’re probably also exploring your choices and comparing it in opposition to other obtainable steroids.

There’s a sea of steroids out there, and choosing the

right one for your needs may be tough.

I’ll have Aromasin on hand but will not use it till

estrogenic unwanted facet effects begin to happen.

In the 5th week, if I react nicely (ie. do not get a loopy amount of

sides), I’ll add 20mg of Anavar every day. Then on the seventh week, I Will up the

dose of Take A Look At to 350mg per week until the tip of the cycle, relying on how I tolerate it.

I Will take the final shot of Check on Thursday evening of

week 15 and take the final tab of Anavar on the same day, or

on Saturday, the last day I work out that week (let me know which one

could be better). I’ll then wait 4-5 weeks after the final shot to permit 5 half-lives to cross for the enanthate ester after

which begin a PCT of Clomid for 4-6 weeks. There is a danger when purchasing any anabolic steroid

on the black market; nevertheless, it could presumably be argued that Anavar is especially

precarious as a result of its high market value. Consequently, a typical scam we now have seen is for sellers to dilute or substitute oxandrolone for methandrostenolone (Dianabol), which may be manufactured at a fraction of

the price.

These effects make Anavar an effective device for fat loss throughout cutting cycles.

That stated, it rapidly rose to fame within the health world as

a way to extend lean muscle mass without accruing any estrogen aspect and very few androgenic ones.

Anavar is a fast-acting steroid that starts exhibiting outcomes within a

couple of days of use. However, the precise time when it begins to

work can differ relying on a quantity of components, together with the user’s age, gender,

weight, and dosage. In basic, Anavar starts working inside

2-4 days of use, and users can start noticing modifications in their body composition,

energy, and endurance.

Anavar and Dianabol are additionally in style anabolic steroids, but they have

different effects and purposes. Anavar is prized for its capacity to construct muscle

mass while burning physique fats, making it appropriate for cutting phases.

Dianabol is a fast-acting oral steroid with a 3-6 hour half-life, identified for its muscle-building potential throughout bulking cycles.

References:

Winstrol Steroid

2025-04-08上午1:30

Anavar for girls is commonly faked on the black market, with

individuals displaying positive results without really having used the product.

Thus girls ought to order a testing kit before

they take anavar, or any similar managed substance.

Though girls naturally solely produce small amounts of testosterone by way of their ovaries, it’s nonetheless a vital for male hormones functioning and well-being.

Greater testosterone levels increase sex drive in girls, this improve in libido usually isn’t enough to

be a drawback, until a woman is attempting to stay celibate.

Thus, weighing yourself to trace fats loss on Anavar is of little use,

as a end result of its simultaneous muscle-building properties.

Anavar is primarily used as a cutting steroid, so if a woman’s aim

is to construct large amounts of muscle, other steroids would be more beneficial (such as Anadrol).

By implication, it will increase libido, confidence, gym aggression, and nicely being.

Clenbuterol is a beta-2 agonist that stimulates the central nervous system, resulting in elevated

metabolic rate and fat burning. Anavar, however, is an anabolic

steroid that promotes muscle development and fats loss.

It works by rising your metabolic fee, which in turn increases

your physique’s core temperature, resulting in a better rate of calorie burning.

If you discover that you’re tolerating it nicely, you

possibly can extend your cycle length. It’s

essential to notice that everybody responds in a special way to Anavar, so you could

want to regulate your dosage or cycle size relying on how your body

reacts. Be sure to speak with a health care provider before starting any new supplement or medicine.

On the days that you simply don’t prepare, you want to

nonetheless take Anavar very first thing within the morning.

This will ensure that the steroid is out of your system by the

point you go to bed. You additionally have to take into accounts

your personal personal tolerance to the drug. If you discover that you’re tolerating it

properly, you can improve the dosage steadily.

Moreover, we’ve discovered regular cardiovascular coaching to have a notable reductive impact on blood strain in our patients.

These results are typical of Anavar’s results; nevertheless, if customers eat in a calorie surplus, fats loss is prone to be less than these illustrated above.

Thus, diet stays an necessary factor in determining physique composition on Anavar.

These include adjustments in lipid levels and liver toxicities

(particularly when it’s used for long-term or high-dose usage) as nicely as the

inhibition of testosterone’s natural manufacturing.

Anavar has very low androgenic (masculinity) properties in comparison with numerous different Anabolic steroids.

This reduces the prospect of virtualization, and the looks of male traits in girls,

including vocal enlargement body hair development, and clitoral progress.

However, it’s necessary to notice that like all steroids, Anavar could cause side effects,

and its use should be carefully monitored to avoid potential health dangers.

Some of the potential side effects of Anavar for

ladies embody zits, hair loss, and adjustments in menstrual cycles.

It’s a well-liked selection for bulking up and cutting fat, and it

has several advantages that make it superior to other steroids.

For one factor, Anavar does not cause as a lot water retention as different

steroids, permitting you to keep a more outlined physique.

It additionally causes less liver damage than other

medicine, making it a safer alternative for people who are concerned about their health.

Anavar can additionally be effective for bulking up and reaching a lean, ripped physique.

It’s a preferred alternative for athletes looking to improve their efficiency, and

it’s been shown to help with strength and velocity.

However, there aren’t any studies to suggest that wild

yam is effective for constructing muscle. Nevertheless, this is identical story as

soy protein, as the amount of whey in anvarol is tiny (0.45 grams per day).

In phrases of pure weight loss, you’re in all probability taking a look at shedding around

12lbs in a four week cycle. Anavar is amongst the “best steroids” to take if you’re decided to burn fats, construct muscle, and

keep your female magnificence. In bodybuilding circles,

many imagine Anavar to be the safest steroid ever created.

Doctors do prescribe Anavar to children with cachexia, demonstrating its low toxicity however

this doesn’t mean that it’s unlawful and unsupervised use is secure as properly.

Some folks say they don’t notice much on anavar, which I put all the means down to a too-low dose.

The dosage ranges supplied are basic guidelines and must

be adjusted primarily based on your individual targets, experience stage, and tolerance.

For those unaware, every week we now have a particular steroid or

PED up for discussion. The aim of those threads is to generate discussion concerning the

posted compound and get a extensive variety of person experiences and feedback about it.

This is all anecdotal, in fact, and you should take these critiques with a grain of

salt.

Diligent training and healthy dietary habits are essential for attaining these results.

In terms of bodybuilding, this potent drug is usually used as a device for muscle growth and efficiency enhancement.

Although not as highly effective as some other steroids, it

works efficiently in selling lean muscle mass, making it highly sought after within the bodybuilding community.

In conclusion, Anavar is often a priceless device for bodybuilders and athletes when used appropriately and at

the aspect of correct food plan and exercise. Its results on muscle mass, fats reduction, and performance enhancement make it a preferred

alternative for these in search of to improve their overall

fitness and athletic skills. For males, an elevated firmness in muscles, lean mass development and a notable discount

in physique fat will probably be noticed.

Ladies are also more prone to creating muscle cramps

and tremors when taking Clenbuterol. In addition to the bodily advantages, you can even expect improved power levels

and mental clarity. Clenbuterol is a powerful stimulant that can give you a lift of vitality,

while Anavar has been found to enhance focus and motivation. Nonetheless,

if you would like to shed weight and build muscle, then Anavar is the higher choice.

Finally, the selection between Clenbuterol and Anavar for endurance and

stamina will come down to individual needs and objectives.

References:

best non steroid supplement for muscle growth

2025-04-08下午3:29

Sadly, if unwanted effects referring to menstruation and fertility do develop, they’ll continue to be an issue even after you’ve stopped taking Clen. Clenbuterol has not been studied in depth for its results and dangers

in humans at efficiency doses, so the precise cause of these critical problems isn’t nicely understood.

Needless to say, utilizing Clenbuterol at high doses is a severe

health danger and ought to be averted in any respect prices.

But even at lower doses, some unlucky users of Clenbuterol

can discover themselves experiencing some very alarming heart-related side effects,

which may quickly flip into long-term and lifelong unwanted side effects.

The principle guiding steroid utilization must be balanced, consciously respecting private

well being limits and physiological responses to the substance.

A strengthening cycle capitalizes on the aptitude of Oxandrolone to augment strength

with out precipitating excessive weight acquire. It is

advantageous, particularly for athletes who need to adhere to weight classes.

Strength enhancement may not align with substantial muscle size increment,

further underlining its suitability for athletes somewhat than conventional bodybuilders.

I’m going to skip over the typical whey protein and creatine as a end result

of we all already use those two varieties.

TRT is what makes you ordinary again, and there isn’t anything incorrect with being normal!

So until you might be really into health and/or strength,

no, it’s not value it.

Some pimples on skin may seem, and that’s when you’re genetically predisposed to get them.

Nonetheless, Testosterone isn’t a fats burning

compound and is definitely not a compound that you could anticipate

miracles from, particularly when speaking about fat. In case

you’re already having quite an excellent and around stomach, anticipating abs

in a single day from using it or even from using the steroid stack can be an enormous mistake.

Was initially developed within the Sixties and was shown to

have a quantity of therapeutic applications.

This article will talk about commonplace doses of Anavar but emphasizes that people ought to seek the advice of

with healthcare professionals earlier than contemplating steroid use, as each person’s health

status and dangers differ. Like Dianabol and Deca Durabolin, cycling Anavar and Anadrol isn’t

something that many steroid-users do, however that’s not to say

it can’t be accomplished and used efficiently. In truth, apart from Trenbolone and Halotestin, there isn’t a better pairing of

steroids for energy than Anavar and Anadrol.

This could also be much less extreme in comparability with an Anadrol-only

cycle; nonetheless, we have noticed hypogonadism transpiring from Anavar-only cycles.

With Out PCT, testosterone deficiency may last for a quantity of weeks or

months. Thus, an incremental dosing technique can improve fats loss all through

the cycle. When adopting a dosage of 10 mg/day for 5

weeks, the chance of growing masculinizing unwanted aspect effects could

additionally be decrease due to the modest dose and shorter cycle period.

Performing regular cardio throughout a cycle may even assist to manage blood strain. Testosterone is

necessary for well-being, libido, confidence, and vitality

levels in ladies. This can enhance muscular endurance;

hence, why some athletes attempt to get hold of a successful

edge by taking steroids. Nevertheless, top-of-the-line advantages of Anavar is that it burns both visceral and subcutaneous

fat, serving to girls achieve a smaller waist.

It is predicated on DHT, an androgen, so it must be no shock

that you could expect to see exercise on this space.

These unwanted effects cover points that the majority

steroid users shall be conversant in, including potential pimples and hair loss or male sample baldness.

The major goal of combining Proviron with Dianabol is to reduce a

variety of the bloating/water retention that Dbol is famous for.

In this sense, we’re using Proviron in a bulking cycle, however essentially,

it’s a supportive compound and will not affect your muscle positive

aspects (that’s what Dbol is for). With Out liver toxicity

risks, I’ve been comfortable utilizing Proviron for 3 months at a time.

Anavar enhances metabolic rate and lipolysis15; this makes Anavar a particularly highly effective fat-burning steroid the place calories and saved body

fat are efficiently utilized as power. Your metabolic price will

enhance, and you will discover burning fat faster and extra environment friendly.

Naturally, your food regimen should assist fat loss, which will always be the case on a chopping cycle.

As with any anabolic steroid, Oxandrolone use doesn’t usually lead to unwanted

effects, but if abused, it may end in potential antagonistic effects that users ought to concentrate on. By understanding these

side effects and taking appropriate preventative measures,

individuals can goal to reduce potential dangers and maintain their overall well-being.

An aggressive PCT of hCG, Nolvadex, and Clomid may even be required on this testosterone/trenbolone cycle to prevent testosterone deficiency (and to assist retain gains).

Nonetheless, anecdotally, we’ve seen SERMs similar to Nolvadex exacerbate progesterone levels

on Deca. Nonetheless, AIs can worsen blood stress ranges, so our patients only take them if

the nipples begin to turn into swollen. Water retention is sort of sure with this duo,

inflicting users bloating and muscle smoothness.

References:

2ahukewjkv_v5usvnahvlip4khu09akmq420oa3oecakqcq|the best steroids for muscle growth – https://bug-bounty.firwal.com –

2025-04-08下午4:00

Your style is really unique in comparison to other people I’ve read

stuff from. Many thanks for posting when you’ve got the opportunity, Guess I’ll just bookmark this page.

Feel free to visit my web site: telegram engagement

2025-04-08下午9:15

I am curious to find out what blog platform you happen to be working with?

I’m experiencing some small security problems with my

latest website and I would like to find something more safe.

Do you have any suggestions?

My web-site: Bokep Indonesia

2025-04-11上午9:05

Whereas skilled steroid users might be much less delicate

by way of years of cycles and can experience milder gains.

In our experience, an AI (aromatase inhibitor) is

the most suitable choice for counteracting the possibilities of

enlarged breast tissue from testosterone and trenbolone. Nonetheless, there’s a drawback with AIs,

as they have the ability to reduce HDL cholesterol and increase blood strain.

Whether Or Not you’re a runner, a weightlifter, or an athlete in any other sport, Trenbolone can give you the aggressive edge

you have to excel. One of the first causes athletes flip to Trenbolone is its ability to increase lean muscle mass quickly.

Trenbolone stimulates protein synthesis at a high rate, permitting the muscle tissue to repair and develop sooner.

Unlike some other steroids, Trenbolone promotes muscle gains with minimal water retention, leading to a lean, defined look.

Trenbolone acetate is a synthetic anabolic steroid of the nandrolone group.

Regardless Of being unlawful for human use

in lots of international locations, trenbolone

is utilized by some individuals for growing muscularity, strength

and fats loss. Part of its appeal is resistance to aromatisation, which suggests it doesn’t convert to estrogen within the physique.

We have found the chance of gynecomastia to be excessive

with this stack, with estrogen levels rising in the presence of Anadrol and testosterone.

Anti-aromatase inhibitors have proven to be ineffective with Anadrol in our expertise,

as it doesn’t convert to estrogen. Gynecomastia is feasible due to Anadrol

being highly estrogenic and the progesterone activity present with trenbolone.

Crazy Bulk is our beneficial supply for legal steroid alternate options, based on thousands of optimistic reviews on verified platforms corresponding to Trustpilot and Feefo.

This is undesirable information, considering blood stress is already prone to

be high throughout this cycle. Nevertheless, an anti-estrogen is normally

efficient in treating high progesterone unwanted effects.

This occurs due to a rise in blood strain, indicating decreased blood flow to the guts;

thus, deeper breaths are needed to increase oxygen provide.

It is not uncommon for users to experience shortness of

breath when strolling up the steps or doing mild train on tren. Nevertheless, under are

17 effects that we’ve found consistent in trenbolone

customers at our clinic. Nevertheless, others argue that tren’s adverse effects are exaggerated and not notably worse than these of other

anabolics. Nevertheless, microdosing makes another vulnerable

to developing a dependence and tolerance to the drug. This is as a

result of your body is constantly flooded with the substance and soon becomes habituated to its presence (tolerance) or

needs the substance there to perform normally (dependence).

Suppose again should you believe that’s too low – remember that Tren Acetate is a number of instances more powerful than testosterone.

At the upper finish of the newbie dosage range is 150mg per week, and this might very nicely be the most Trenbolone

you’ll want to take. Potential unwanted side effects of using Tren Hex are coughing matches after injecting, insomnia, excessive

sweating, temper modifications and aggression, acne, hair loss on the head, and body

hair development. As with all Trenbolone cycles, it’s all the time beneficial to

make use of Trenabol alongside testosterone to make

up for the slowdown in natural testosterone manufacturing.

When it involves the authorized considerations of Trenbolone

Acetate, it is essential to be aware of the laws and rules

specific to your country or area. In some international

locations, Trenbolone Acetate is strictly prohibited without a legitimate

prescription from a licensed medical professional.

The possession, sale, or distribution of this compound without correct authorization can result in legal penalties.

It is advisable to analysis and perceive the legal guidelines governing

the utilization of anabolic steroids in your jurisdiction to make sure compliance and avoid

any legal issues. Consulting with a healthcare professional or

authorized expert can provide priceless guidance in navigating the authorized landscape.

Tren possesses potent fat-burning properties, making it efficient for slicing cycles.

It stimulates the metabolism, increases thermogenesis, and promotes lipolysis, leading to accelerated fats loss.

Click right here to discover the mind-blowing earlier than and after transformations of Trenbolone users.

Moreover, Trenbolone stimulates lipolysis, the breakdown of saved fats cells, releasing fatty acids into the bloodstream to be used as a supply of

vitality. This process particularly targets cussed fats deposits,

similar to these found in the stomach, hips, and thighs, leading to a extra toned and sculpted

appearance. Due to having extreme testosterone suppression, that’s why do

bask in PCT to kick-start endogenous testosterone again to

normal levels again. Testosterone is a light steroid that can easily be stacked with Trenbolone with out dramatically worsening Tren’s unwanted

effects. Throughout the first week of PCT, the dosage will be high which can additional be reduced from the second week of

consumption.

Excessive doses or prolonged use of Trenbolone can increase the chance of liver toxicity and other adverse

results. People must also keep away from different medication and supplements

that may damage the liver, such as alcohol and acetaminophen. Acne is a

pores and skin situation that occurs when hair follicles turn out to be clogged with oil and lifeless pores and skin cells.

Trenbolone can enhance oil production within the pores and skin,

leading to the event of acne.

A trenbolone and testosterone stack may be greatest

for many who wish to gain a significant quantity of

muscle mass. Nevertheless, trenbolone is not recommended for newbies because of its detrimental results on the HPTA

(hypothalamic-pituitary-testicular axis) and its

increased danger of arteriosclerosis (4). Nevertheless, because of trenbolone’s high toxicity, intermediate and experienced steroid users sometimes cycle this steroid as a substitute of beginners.

Trenbolone is used extensively in cattle for development promotion, with over 20 million animals receiving it annually.

In veterinary research, it has shown to enhance feed

effectivity and improve muscle mass in livestock.

It can even enhance the risk of gynecomastia (development of male breasts),

especially when mixed with other steroids that convert to estrogen. Under is an outline of essentially the

most commonly reported trenbolone unwanted facet effects, as noticed in animal studies

and shared by customers in the health group.

An intermediate cycle could embrace an extra compound, in this case, Dianabol,

to provide the cycle a mega kick begin. Testosterone continues to be limited to hormone replacement dosage

on this cycle. An instance of a feminine operating

a Tren Ace cycle will contain those wanting to prepare

for physique modeling competitions.

Trenbolone presents the potential for increased muscle progress, enhanced fat burning, improved exercise performance, and retained muscle mass throughout slicing phases.

However, it is essential to method Trenbolone with caution, following expert

recommendations, and prioritizing your well being and safety.

Educate yourself, seek the assistance of with

professionals, and adhere to correct nutrition, training, and post-cycle therapy tips.

By taking a responsible and informed method, novices can optimize their Trenbolone expertise

and work towards reaching their fitness targets with confidence.

Bear In Mind, always prioritize your well-being and make choices that

align along with your individual wants and circumstances.

References:

steroids Transformation (https://hangoutshelp.net/)

2025-04-11上午9:50

Fine way of telling, and nice piece of writing to obtain data about my presentation subject matter, which i am going to convey in college.

my website; چطور در اینستاگرام پیام محوشونده بفرستیم

2025-04-11下午7:15

Parabolan comes with side effects that embrace androgenic effects,

potential impacts on cholesterol, and reasonable to severe testosterone suppression. Utilizing Parabolan at high doses will increase the chance of its changing into unsafe.

Nonetheless, many individuals use it often at low to reasonable doses, with enough breaks between cycles to allow time for the body to

get well.

Anybody who is in search of the drug merely has to poke

around X or Instagram through the best influencer. The person is then rerouted

to a messaging platform similar to Telegram or WhatsApp.

There a vendor connects directly with the person to trade contact data, iron out the details of the transaction, and finalize issues

on Venmo or PayPal. Let’s face it, when folks inject Trenbolone they

don’t do so due to a pressing want to feel sick or climb

into an early grave. Due to its high androgenic score, it can be

superb for robbing them of their female charms.

The drug also has a very high ratio of anabolic to androgenic exercise.

Trenbolone does not convert to estrogen and due to this fact does not trigger any water retention. I am a muscular guy with a

lot attention and recognition for my physique.

It replicates the muscle-building and strength-enhancing effects of Anadrol, however with out

the undesirable side effects. Deca Durabolin just

isn’t a toxic steroid like Anadrol, so side effects are going to be milder than running Anadrol by itself.

Nevertheless, testosterone shall be extra suppressed post-cycle, so a strong PCT must be used.

If a user’s side effects are important at 50 mg per day, chorus from increasing the dose

to seventy five mg on week four (continuing with 50 mg/day).

This is a steroid with a number of advantages and a few disadvantages you would be familiar with.

Trenbolone will provide you with far more muscle-gaining potential than Masteron, which is more of a pure-cutting AAS.

Relating To unwanted effects, even Dianabol can appear to be an easy AAS to make use of with

a less outrageous facet effect profile in comparability with Tren.

Each Tren and Dianabol are beneficial for short-term use only, however

it is potential to use Trenbolone for prolonged periods at lower doses.

With no two folks being the identical, males will talk

about paranoia, further aggression, jealousy, anxiety, and different emotions that may become harder to

manage as you improve the dose or cycle size.

Tren isn’t a prescribed anabolic steroid and is assessed

as a Schedule III managed substance. This law can vary from one

nation to the next however most all will frown on a web-based purchase.

The solely distinction of true significance is how fast the hormone works, and this is decided by the ester.

The ester doesn’t change the precise functions and traits

of the Tren hormone. The ester also determines how a lot

lively Tren is on the market per milligram.

The bigger the ester the more space it takes up within the compound and the less lively Tren there’s

obtainable per milligram.

However, some customers have reported feeling fatigued while

on Trenbolone. This could possibly be because of the truth that Trenbolone can enhance ranges of the

hormone progesterone, which might have sedative results.

Androgens play a job in the development and upkeep of male

sex characteristics, such as facial and physique hair development, muscle mass, and a deep voice.

We can by no means say that any steroid is

safe for bodybuilding or performance. Whereas a couple of different steroids have medical approval to be used in humans at low doses, Trenbolone isn’t certainly one of them.

Equipoise and Dianabol, working alongside Parabolan and testosterone at alternative degree dosage, will present

one of the most highly effective bulking combos possible.

Discovering the proper dosage is a crucial aspect of harnessing the full

potential of this powerful anabolic steroid. With its reputation for promoting important muscle

progress and enhancing performance, Trenbolone Acetate has piqued the curiosity of bodybuilders, athletes, and fitness enthusiasts alike.

Nevertheless, navigating the dosage landscape can be overwhelming, as optimum usage varies based mostly on individual targets, expertise, and tolerance.

In this weblog post, we’ll delve into the art

of optimizing Tren Ace dose, shedding gentle

on key considerations, potential dangers, and techniques

for achieving effective results safely. In addition to its anabolic

properties, Trenbolone also enhances metabolic price, facilitating

elevated fats burning and promoting a leaner physique composition. This twin motion on muscle growth and fats loss makes Trenbolone

a versatile software for people looking for to sculpt a

physique characterized by each muscularity and leanness.

In this part, we’ll give you a complete overview of the dosage guidelines

that can help you make knowledgeable selections and tailor your

Trenbolone Acetate regimen successfully. This consists of determining the cycle duration, dosages, and

frequency of administration. Consulting with a educated healthcare professional or experienced trainer can provide useful guidance in creating an effective cycle

plan. To mitigate the side effects of Trenbolone, it

is essential to observe the prescribed dosage and cycle size.

References:

natural abs vs steroid abs

2025-04-11下午9:21

hello!,I love your writing so much! share we communicate more about your post on AOL?

I require a specialist on this space to solve

my problem. Maybe that is you! Having a look ahead to look you.

Also visit my web site: kontol besar

2025-04-12下午9:53

Testosterone suppression goes to be extreme, so our sufferers typically

take three PCT dietary supplements (Nolvadex, Clomid,

and hCG) to deliver their testosterone levels again to a traditional vary.

Anadrol is possibly the worst steroid for blood strain, causing hefty rises due

to its disastrous impact on HDL cholesterol levels.

This is due to it stimulating hepatic lipase, an enzyme liable for reducing good cholesterol (HDL), which prevents clogging of the arteries.

Clenbuterol burns a significant amount of subcutaneous fats, just like Anavar; thus,

combining these two compounds will end in important fat

loss. Thus, the hormonal lipolytic effects of Anavar may be preserved even if a person is

sedentary post-Anavar cycle. Analysis signifies that if a person administers

Anavar and does not lift weights, any improvements in muscular energy or mass may be short-term (29).

Due To This Fact, any increase in muscle hypertrophy diminishes following cycle cessation. Some bodybuilders state

that they require Anavar doses of 40 mg so as to see notable outcomes.

This is indicative of the product being underdosed, as 20 mg is more than adequate to experience vital adjustments in body composition. Anavar is the most common counterfeit anabolic steroid we’ve

encountered.

With these hormones controlled, fat acquire is halted and lean muscle

can grow uninhibited. Anavar cycle is a well-liked weightlifting steroid cycle utilized by bodybuilders and

athletes. It is a testosterone alternative therapy that includes taking an anabolic agent, such as

testosterone, along with a reductant similar to cortisol.

If you discover that you are tolerating it properly, you can lengthen your cycle length.

If you are using Anavar for chopping purposes, you will need to use it for a shorter time

frame than if you are using it for bulking purposes. It’s important to

note that everybody responds in a unique way to Anavar, so you could want to regulate your dosage or cycle size

depending on how your physique reacts.

Compare to other options, it is a comparatively safe anabolic steroid

for chopping. So there isn’t a worrying about water retention or gyno when you are biking with

this drug. The exception is when it comes to female

customers, who ought to cycle it on its own. Some folks out there will declare that publish cycle remedy, or PCT, following

a Primobolan cycle isn’t required.

One notable observation throughout the initial

couple of weeks is a rise in energy. Whereas there may not be an explosive development in muscle size just

yet, bodybuilders often observe a substantial enchancment in their functionality

to raise heavier weights and do more intense workouts.

Anavar, on this way, helps kick up the stamina, making ready the physique for the journey forward.

It additionally eliminated water retention because of Primobolan not aromatizing into

estrogen (being a dihydrotestosterone-based steroid). Winstrol,

like Anavar, does not aromatize, making it a suitable steroid

for females coveting a decent, dry, and vascular physique with minimal amounts of fluid retention. For this purpose, the under steroid cycle is often utilized by females making ready

for a competition in a bid to show most muscle definition. We typically

see these side effects persist for a number of weeks or months until endogenous (natural) testosterone levels recover.

Females typically solely have 5–10% of testosterone compared to males; nevertheless, it remains an essential hormone for

confidence, power, motivation, and sexual want and satisfaction. Anavar dramatically increases protein synthesis, nitrogen retention, and IGF-1 (insulin-like development

factor) ranges, inflicting significant improvements in muscle hypertrophy (size) and energy.

One of the appealing things about var is that it isn’t aromatized by the

physique.

This is because of the greater risk of virilization, or the event of

masculine traits, in ladies. It can additionally be important to note that Anavar cycles for females are sometimes shorter,

with a period of 4-6 weeks. It promotes fast fats burning and weight loss, builds muscle mass and power, improves efficiency, and enhances sexual libido and stamina.

Females can expect average will increase in lean muscle

tissue and a discount in fats mass due to enhanced protein synthesis and nitrogen retention within the

muscle cells. Anavar causes reductions in HDL ldl cholesterol, probably

inflicting hypertension (high blood pressure) and rising

the risk of arteriosclerosis. Nonetheless, in our lipid profile testing,

Anavar solely causes gentle cardiovascular strain in comparison with other anabolic steroids.

Over the years var has frequently been a staple for pre-competition bodybuilders and athletes where speed and

lean muscle gains are a precedence.

Always seek the guidance of with a healthcare professional who can provide personalised recommendation based mostly

on your health standing and goals. It’s additionally important to suppose about

post-cycle therapy (PCT) after completing an Anavar cycle.

PCT is used to help restore pure testosterone production, which may be suppressed during steroid use.

The specifics of PCT can range, and once more, it’s essential to hunt steerage from a healthcare skilled.

Although it’s well-liked among males, it is much more so amongst girls as a result of an absence of virilization side effects.

A natural bodybuilding supplement designed to mimic the fat loss effects of Anavar with

out the unwanted aspect effects. In summary, post-cycle therapy plays a

vital role in serving to the body recover from an Anavar cycle.

During these cycles, people ought to continue to prioritize

correct diet, intense training, and adequate rest

for optimal outcomes. It is essential to focus on potential unwanted

effects and frequently monitor blood markers and total well-being.

Before starting an Anavar cycle, it’s essential to seek the guidance

of with a healthcare professional to determine the suitable dosage and to watch your progress all through

the cycle.

This makes it a superb athletic enhancing steroid, a unbelievable cutting steroid.

Oxandrolone is a c-17alpha alkylated anabolic steroid this refers to a structural change of the hormone at the seventeenth carbon place.

That permits it to be ingested orally and survived the primary

cross via the liver, a essential trait in order for its survival.

Like most oral steroids, Anavar can give you some crazy pumps in sure muscle groups – typically

so unhealthy you could’t even end a workout.

In medical analysis, the one incidence of gynecomastia occurring

from oxandrolone was in a research carried out on adolescent boys (12).

33 circumstances of gynecomastia had been reported; however, these findings are contradictory

to different analysis in adults. Thus, the chance

of gynecomastia seems to considerably increase if kids utilize Anavar for extreme intervals throughout puberty.

These children were taking average doses of Anavar repeatedly for six months to eight

years. In our experience, ladies can typically expertise

superior results in muscle mass in comparability with males on Anavar, even with a modest dose of 5–10 mg per day.

This is false as long as you’ve a healthy liver and don’t

abuse medicine or alcohol already. We have seen plenty of bloodwork proving that utilizing N2guard in your cycle prevents

extreme liver toxicity and you ought to use it for eight weeks.

References:

legal supplements Similar to steroids

2025-04-13下午6:38

One of the less spoken-about benefits of Anavar is a attainable increase to your total temper.

The identical can’t be mentioned for lots of other steroids,

which may probably cause anxiousness and increased anger as a substitute.

With Anavar’s capacity to reinforce recovery23, you’ll notice a rise within the frequency

of your exercises. At the identical time, the intensity and length

of your coaching substantially improve because your body recovers more efficiently.

In the top, all this means higher, sooner results thanks

to the wide-ranging results of Anavar. So, whereas these

are two crucial benefits of Anavar, they aren’t the one

ones. Even if chopping is your primary cause for using Anavar, you’ll get many different constructive

effects that can only add to your features and total results.

Such use will usually last 2-4 weeks with a small

break after use before implementing the subsequent 2-4 week cycle.

These who complement with Anavar in the course of the cutting part may even burn fats

at a extra environment friendly fee. Regardless of how

highly effective the direct lipolysis trait is or isn’t,

the metabolic price will still be significantly enhanced.

As Quickly As lean, the individual will also find he seems

harder and more outlined. This is commonly accompanied by enhanced vascularity,

and an total tighter look. Most underground labs will carry the same tab or capsule for round one to 2

dollars per tab.

Combining Anavar with different steroids or performance-enhancing

medicine increases the danger of harmful unwanted side effects.

It’s also sensible to avoid high-fat diets

that may further disrupt levels of cholesterol. Lastly, avoid prolonged use to attenuate the risk of long-term

damage to your physique. It can also be used to alleviate bone ache due to bone loss (osteoporosis).

Decreasing physique fats is doubtless considered one of the major concerns for many feminine bodybuilders.

For ladies trying to lose fat and achieve a toned physique,

Anavar’s ability to burn fat while preserving lean muscle

mass is unparalleled.

If you experience any severe unwanted effects

while taking Anavar, you must stop taking the medication and talk

to your healthcare provider immediately. There is not

much difference in Anavar dosage for bodybuilding functions whether you’re a man or

lady. It is crucial for ladies to make use of Anavar

with warning due to the potential for virilization, which is the event of male-like characteristics.

Your total experience with Anabolic steroids matters in relation to your Anavar dosage.

It was first created in 1964 to help people who had lost a lot of weight due to sure

medical circumstances achieve back the burden they’d lost.

Anavar (oxandrolone) is a man-made steroid, similar to the naturally occurring steroid testosterone.

We will also talk about the method to cycle Anavar, in addition to provide tips about

the way to decrease the danger of unwanted effects.

Nevertheless, it have to be mentioned that oxandrolone is taken into account a poor “bulking” steroid amongst male bodybuilders.

But then again, it is an excellent drug for ladies who are wanting

to add lean muscle mass. Now that we have coated the fundamentals of Anavar

and how it works, let’s further discuss the benefits,

unwanted effects, bodybuilding/sports usage, dosage and legality.

Anavar also can allow you to lose fats, build lean muscle

mass, and improve your athletic performance. All of these benefits make Anavar an excellent

choice for athletes and bodybuilders alike.

Some bodybuilders state that they require Anavar doses of forty mg to be able to see notable outcomes.

This is indicative of the product being underdosed, as 20 mg

is greater than sufficient to expertise vital adjustments in body composition. A widespread scam we’ve been made conscious of is dealers

labeling merchandise as Anavar, however the raw ingredient being Dianabol.

You’ll be lifting heavier weights and should

discover your lifting action improves with that strength enhance.

A complete vary of different steroids are

generally stacked with Anavar, together with the highly effective fat burner Winstrol, Equipoise, Proviron, Masteron,

or Primobolan. You can count on amazing outcomes with

out water retention with this cycle.

Nonetheless, in my opinion, the best way to avoid any and all unwanted effects are to avoid Anavar at

all cost. Lastly, you have to make positive that you are taking Anavar

on the right time of day. If you’re experiencing side effects that

you’re involved with, you should discuss to your physician as soon as potential.

However it retains its advantages solely when complemented by a wholesome life-style of balanced diet,

constant exercise regime, and adequate rest.

The changes in levels of cholesterol caused by Anavar can lead to an increased

risk of heart illness, coronary heart assaults, and strokes.

Men who already have cardiovascular points or are in danger for them should be

particularly cautious when contemplating Anavar use.

Consequently, BTG was able to considerably enhance the

price of Anavar by 1,200%. This medication may interfere with certain lab checks (such as thyroid function tests),

probably inflicting false take a look at outcomes.

Older adults could additionally be at larger threat for

prostate/liver issues and swelling of arms/legs whereas utilizing this drug.

Before utilizing oxandrolone, tell your physician or pharmacist in case you are allergic

to it; or when you have any other allergic reactions. This product may contain inactive components, which can trigger allergic reactions or other issues.

Rarely, males could have a painful or extended erection lasting four or more hours.

If this occurs, cease using this drug and get medical help right away, or everlasting problems might happen.

References:

cutting steroids for Sale

2025-04-14上午9:23

With some Clen expertise underneath your belt, a beginning dose of 40mcg can set the stage for growing it gradually as you see

match. One technique I like is to stay with one dose for 2 weeks, then increase it by 20mcg.

A simple 6-week cycle with this strategy takes

you from 40mcg to 60mcg, then 80mcg for the ultimate two

weeks. Most commonly for those taking part in contests, Clenbuterol might be used in the

two months leading as a lot as the contest,

where the physique is already very lean. Often thought of extra stimulant

than a real steroid, Clenbuterol is infamous as a robust fat burner that works by increasing

thermogenesis and thus raising the metabolism. This helps burn off stored fat as the

body is consistently at a heightened metabolic rate,

even at relaxation.

One generally used trick to effectively reduce the value of

Anavar is to take it with 200ml of grapefruit juice as an alternative of water.

There is an enzyme in the intestines and liver, generally known as CYP3A4, which plays a job in breaking down foreign molecules in the

physique. Common cardio or high-intensity

interval coaching can be performed, which

is in a position to help to decrease blood pressure, whilst assisting in burning more fat.

This is problematic for girls because Dianabol greatly

increases the chances of virilization. Anavar for women is usually faked on the black market, with people exhibiting positive effects without really having

used the product. Thus ladies should order a testing kit before they take anavar, or any similar

controlled substance.

Most energetic females don’t actually care about constructing a ton of muscle – they simply wish to be lean, fit and toned.

Everybody is genetically completely different and will have a novel response, as

far as the advantages and unwanted facet effects of steroids are concerned.

It is rumored that Primobolan was actually considered one of Arnold Schwarzenegger’s favorite steroids, during the peak of his bodybuilding profession. Oral Primobolan is

believed to be much less tense on the liver than different popular oral steroids.

Even although the aim of this text is that of discussing the most

effective Primobolan cycle for ladies; we must first perceive how the peculiar steroid works.

With different well being supplements you must await a number of months

to see results, if ever. The finest approach to avoid

these side effects is to ensure you don’t take greater than you’re alleged to as a outcome of overdosing will trigger problems.

While the before and after photos are certainly persuasive it’s necessary you keep track of the facts and

know what you’re getting into. Anavar

before and after men photos exhibits that it actually works, but that doesn’t change the reality that it’s

going to have some side effects.

How a lot muscle you’ll gain will also depend on the dose,

how many weeks you cycle for, if you combine steroids together in a

stack, your food plan, workouts, and your genetics. Like clenbuterol,

HGH isn’t formally a steroid, but it’s been added to this listing, as many bodybuilders mix this in their steroid cycles.

And its results are very steroid-like, with it constructing muscle and

burning fat. Anadrol is called one of many more popular medication for gaining sheer dimension and power.

Fairly famous amongst strength and power athletes, it may

additionally be used to realize lean muscle mass.

Designed that can assist you construct lean muscle mass and probably even assist with fats loss, D-BAL is an actual sport changer to anyone seeking to

degree up. This particular person went from 159lb to 172lb

in three weeks of taking 20mg of Dianabol.

Health enthusiasts and athletes usually flip

to this steroid for its distinctive benefits.

These who use this substance typically report increased energy,

decreased physique fats, and enhanced bodily

efficiency. It’s crucial to remember, though, that whereas the outcomes could also be spectacular, this substance ought to always be used responsibly and under professional guidance.

Anavar works by mimicking the results of testosterone, a naturally

occurring male intercourse hormone. When Anavar enters the body, it binds to androgen receptors, that are present

in varied tissues all through the body, including muscle tissue.

This binding activates the androgen receptor, which

in flip triggers a cascade of cellular events that in the end results in an increase in muscle protein synthesis.

Oxandrolone is used to help promote weight gain after severe weight reduction because

of surgery, injury, or persistent infections. It can be used

to help offset the muscle losing caused by most cancers, HIV,

and different chronic sicknesses. Moreover, a

nutritious food regimen, complementing your exercise routine, can considerably contribute to

preserving the lean muscle mass and physique definition achieved through the cycle.

As the 12-week cycle nears completion, the fruits of

Anavar results is predicted. Lean muscle achieve, strength enhancement, fat loss, and increased body definition are probably achievements to look forward to.

The last outcomes heavily depend on private elements such as exercise intensity, food regimen, and inherent

genetics, so keep in mind that individual experiences can differ.

Because it’s well known that Anavar hardens the muscles whereas also serving to retain muscle mass while you’re eliminating fat.

Most female Anavar users won’t require or want to take dosages at such a high vary, instead

sticking to a range of 5mg to 15mg day by day.

This will be enough for most ladies to ship exceptional fat-burning and physique

composition enhancements. The degree of that is thought of quite excessive and, as anticipated, rises the upper your dosage of

the steroid is. For this cause, stacking a testosterone steroid with Anavar is at all times ideal, and post-cycle remedy is critical to restore regular hormone perform.

All steroids come with some negatives, but Anavar is on the decrease end of the dimensions in terms of side effects and dangers.

Most of those will only be of concern if you’re using doses that are too excessive

or using the drug for longer than really helpful durations.

One lady had blood tests taken pre- and post-Ostarine cycles,

and although her general well being remained wonderful, she experienced a modest increase in cholesterol (3).

Regardless Of being an insignificant elevation, ladies suffering from hypertension should use caution. This is the widespread consequence

for females who utilize conservative dosages and adhere to standard cycle protocols.

The benefits of Ostarine for ladies are basically the identical as the benefits for

males. Nevertheless, certain results are more amplified and promising in ladies, such

as the level of muscle achieve. The above transformation is typical for a steroid-newbie, who’s doubtless used Dianabol or Testosterone.

One cycle of steroids ends in a acquire of roughly 15-25lbs and customers will discover gains thick and quick.

This can cause problems like male breast growth, small testicles,

and low intercourse drive. Whereas Clenbuterol

can potentially aid in one’s fitness journey,

it’s not a one-size-fits-all situation. These particular

well being circumstances, often known as contraindications, render Clenbuterol a supplement

higher left on the shelf. Another means Clenbuterol contributes

to weight reduction is by enhancing bodily performance. It boosts stamina and endurance,

allowing you to bear extra intense exercises. A greater level of bodily

activity naturally signifies more energy burned,

which then propels your weight reduction journey. As properly as directing your body to make use of fat as gas,

Clenbuterol suppresses your appetite.

References:

are testosterone pills steroids (jobsinsidcul.in)

2025-04-14上午11:08

Does your website have a contact page? I’m having

problems locating it but, I’d like to send you an e-mail.

I’ve got some ideas for your blog you might be interested in hearing.

Either way, great website and I look forward to seeing it expand

over time.

Here is my web page: indian porn

2025-04-16上午3:23

Males on a slicing cycle with Anavar can expect an outstanding fats loss, and it will be quite fast as a end

result of Anavar is a quick-acting steroid that you’ll solely use for eight

weeks max. Exceptional fats loss might be seen on this

stack, and it’ll come on quickly. Count On an increase in energy and endurance, however the unwanted facet effects of Clen can hurt your exercise

capability (lowering the dose is right if you’re delicate to

stimulants). Anavar will provide the capability to build muscle and maintain energy while

dieting. It is, nonetheless, useful as a average lean mass gainer for men and

efficient for ladies when stacked with Primobolan or Winstrol.

Stacking Anavar will virtually solely be for

cutting and recomposition cycles for male customers.

We advise those with elevated blood stress or cardiomyopathy of their household to avoid all anabolic steroids.

Turinabol and Anavar are among the many best steroids in regards to security, based on our patients’ labs.

Although all anabolic steroids trigger a negative impact on a user’s general well being, these two compounds

are the least destructive. Abuse of Turinabol, when it comes to high dosages

or prolonged cycles (past 5–6 weeks), will increase the danger of masculinization.

Anavar raises T3 by making TBG (thyroid-binding globulin) less effective and TBP (thyroxine-binding prealbumin) more practical.

This is useful information for bodybuilders, as T4 (thyroxine)

is the inactive thyroid hormone, and T3 is the hormone that

stimulates fats loss.

Bear In Mind, everyone’s physique is unique, so it’s

important to listen to your body and make adjustments accordingly.

Mix the following tips with dedication, self-discipline, and a optimistic mindset to unlock the empowering benefits of Anavar dosing on your fitness journey.

Novices may want to contemplate beginning with 30 milligrams per day, however they

should be warned that such a small dose may have no impact on sure people.

Beginning a reduction cycle with 50 mg per day

is an appropriate place to begin. Diuretics are another option, however they don’t

appear to be recommended for bodybuilders since they might place

further pressure on their kidneys and lift their danger of developing

renal sicknesses. In most instances, the degree of liver

stress generated by Anavar is insufficient to

warrant fear. This is due to the truth that the liver

is a remarkably resilient organ, even when abused.

At one end of the spectrum is pure testosterone with no esters connected, similar to testosterone suspension.

This causes a reasonably speedy spike in serum testosterone, which

stays elevated for under a short time period.

An ester is a carbon chain hooked up to the testosterone molecule

that slows the release of the hormone within the physique.

Firstly, whenever you inject Sustanon 250, the anabolic hormone you would

possibly be administering is testosterone. Tren could overstimulate the sebaceous glands in genetically sensitive users, causing acne vulgaris.

Anavar is much less probably to do that, although it is a potential aspect effect for

these with naturally oily skin, increasing the chance of

blocked pores. 1) Begin by taking a low dose of Anavar

and slowly increasing the dosage until you attain your required level.

They also supply free worldwide delivery (including

the Usa, UK, France, India, Germany, Europe & Australia), and

every third item is free. If you’re using Anavar based on the recommended dosage and for

at least two months, you need to start seeing outcomes within the first few weeks.

It also helps to preserve muscle mass when you’re cutting energy,

so you don’t have to worry about shedding the progress

you’ve made.

This is undoubtedly a major profit that Primo has