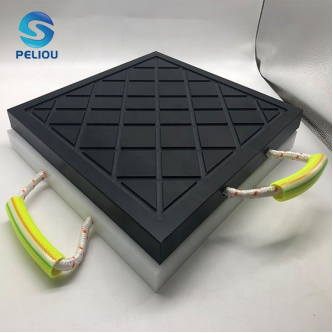

Crane Pads

561Peliou crane pad is made of UHMWPE material, the finished product is lighter and easy to carry, With super durability and wear resistance, can meet...

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

As a common equipment in construction engineering, the crane legs are used to support the weight of the crane and maintain its stability. When using the support legs of the crane, it is necessary to select suitable pads to ensure their support and stability. So, which type of cushion block is the most suitable?

Firstly, the material of the cushion block should have a certain degree of hardness and wear resistance to ensure that it can withstand the weight of the crane and the friction of the ground. Generally speaking, the commonly used materials for crane leg pads include rubber and steel plates. Rubber cushion blocks have good cushioning and seismic performance, which can effectively reduce noise and vibration, while steel plate cushion blocks have high load-bearing capacity and wear resistance, suitable for supporting heavy cranes. Therefore, when selecting cushion block materials, it is necessary to make a reasonable selection based on the weight of the crane and the environmental characteristics.

Secondly, the shape and size of the cushion block are also very important. Generally speaking, the shape of the cushion block should match the base of the support leg and be able to evenly transmit the support force to the ground. In addition, the size of the cushion block should also be reasonably selected based on the size of the legs and the slope of the ground to ensure the stability and safety of the legs. When using the crane, the cushion blocks should be tightly installed at the bottom of the support legs to avoid displacement or tilting during the support process.

Finally, it should be noted that when selecting cushion blocks, environmental and safety factors should also be considered. When using a crane on damp or uneven ground, pads with anti slip and drainage functions should be selected. When selecting new materials, ultra-high molecular weight polyethylene pads with characteristics such as UV resistance, acid and alkali resistance, high load-bearing capacity, and non water absorption should be selected to improve their durability and safety.

In summary, selecting appropriate support leg pads for the crane is crucial for ensuring the safety and stability of the crane’s operation. When making a selection, it is necessary to comprehensively consider the weight, ground environment, and safety requirements of the crane, and select cushion blocks with appropriate materials, shapes, sizes, and functional characteristics to meet the support requirements of the crane legs.

Peliou crane pad is made of UHMWPE material, the finished product is lighter and easy to carry, With super durability and wear resistance, can meet...

View detailstruck outrigger pads

View detailsHDPE this knowledge can help you to buy your most satisfactory outrigger pads in Peliou! All our staff will provide you with the best cost-effecti...

View detailsDo you want to buy ground protection mats for sale ?

View details

I’m not that much of a online reader to be honest but your sites really nice, keep

it up! I’ll go ahead and bookmark your website to come back down the road.

Cheers

Look at my blog :: p1961821

2025-02-06下午5:50

Pretty great post. I simply stumbled upon your blog and wanted to mention that I’ve really loved browsing your weblog posts.

In any case I’ll be subscribing for your feed and I’m hoping you write once more

soon!

Have a look at my web page: Russia beauty supplies

2025-02-07上午9:07

I don’t know whether it’s just me or if everybody else experiencing problems with your blog.

It appears as though some of the written text

in your content are running off the screen. Can someone else please

provide feedback and let me know if this is happening to

them as well? This could be a issue with my web browser because I’ve had this happen before.

Kudos

Check out my website … tell me about fitspresso

2025-02-12下午1:01

Hi! I realize this is somewhat off-topic however I had to ask.

Does running a well-established blog like yours require a massive amount

work? I’m completely new to blogging however I do

write in my diary on a daily basis. I’d like to start a blog so

I will be able to share my personal experience and views online.

Please let me know if you have any kind of ideas or tips for brand new aspiring blog owners.

Thankyou!

Look into my web blog bảng hiệu alu (Dianne)

2025-02-14下午10:37

I really like it when people come together and share thoughts.

Great site, keep it up!

Here is my blog post; QilexoTrader 2.6 A

2025-02-16上午2:39

Every weekend i used to visit this web site, as i wish

for enjoyment, since this this web site conations genuinely good funny data too.

Also visit my website :: MACAUSLOT88 demo

2025-02-18下午8:19

Manta Bridge

2025-02-23下午7:06

Having read this I believed it was really enlightening. I appreciate

you spending some time and energy to put this short article together.

I once again find myself spending a lot of time both reading and commenting.

But so what, it was still worth it!

Here is my page :: snap saver key

2025-02-26下午10:55

Hello, i think that i noticed you visited my web site thus i got here to go

back the desire?.I am trying to to find issues to enhance my web site!I suppose its good enough to make

use of a few of your ideas!!

my webpage :: how to apply for e-visa for vietnam

2025-03-01上午8:18

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

2025-03-01上午10:24

Hi there! Do you know if they make any plugins to safeguard against

hackers? I’m kinda paranoid about losing everything I’ve worked hard on. Any tips?

Here is my webpage; apply tourist visa usa from india

2025-03-01下午2:35

Hey very interesting blog!

my website; Proxies For Seo

2025-03-04下午9:31

I am curious to find out what blog system you are using?

I’m having some small security problems with my latest

site and I’d like to find something more safe. Do you have any

suggestions?

my site sex hiếp dâm trẻ em

2025-03-06上午12:53

Wow, this paragraph is pleasant, my younger sister is analyzing these kinds of

things, therefore I am going to inform her.

Feel free to visit my blog Bokep Indonesia

2025-03-07上午5:34

I simply could not go away your web site before suggesting

that I actually enjoyed the standard info a person provide to your visitors?

Is gonna be back frequently to inspect new posts

Also visit my site; bästa online casino

2025-03-08上午6:46

I’m extremely inspired along with your writing skills as neatly as with the structure on your

blog. Is this a paid subject or did you customize it yourself?

Either way keep up the nice quality writing, it is uncommon to look a great blog like this one these days..

my blog; dich vu seo

2025-03-08上午11:09

I pay a quick visit each day some blogs and websites to read content, but this blog presents quality based content.

Feel free to surf to my homepage; instant withdrawal casino

2025-03-11上午1:52

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

2025-03-12上午4:20

Hello there! This blog post could not be written any

better! Going through this article reminds me of my previous

roommate! He constantly kept talking about this.

I most certainly will forward this article to him.

Pretty sure he will have a very good read. Many thanks for sharing!

Look into my web blog: situs tawa777

2025-03-12上午9:08

Do you mind if I quote a few of your posts as long as I provide credit and sources back to your blog?

My blog site is in the very same area of interest as yours and my visitors would definitely

benefit from a lot of the information you present here.

Please let me know if this okay with you. Thanks!

Feel free to visit my web-site; malls

2025-03-12上午11:39

Hi there, I log on to your blog like every week. Your story-telling style is

awesome, keep it up!

Here is my site :: سایت شرط بندی معتبر

2025-03-13上午8:49

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

2025-03-15下午7:33

This is a topic that’s close to my heart… Take care!

Exactly where are your contact details though?

Also visit my homepage :: macau penis

2025-03-18下午11:10

Hi, its pleasant piece of writing concerning media print, we all be familiar with media is a fantastic source

of facts.

Feel free to visit my page: mua bán nội tạng người

2025-03-23上午7:41

You really make it seem so easy with your presentation but I

find this matter to be actually something that I think I would never

understand. It seems too complex and extremely broad for me.

I’m looking forward for your next post, I’ll try to get the hang of it!

my web page sbobet888 mobile

2025-03-24下午4:32

Hi, i read your blog occasionally and i own a similar one and

i was just curious if you get a lot of spam comments?

If so how do you reduce it, any plugin or anything you can advise?

I get so much lately it’s driving me insane so any help is very much

appreciated.

my web blog :: real money online casinos

2025-03-25上午3:39

ดี โพสต์, ขอขอบคุณ!

22rich

2025-03-25上午11:46

Hi my family member! I wish to say that this post is awesome, great written and come with approximately all important infos.

I’d like to peer more posts like this .

my webpage – real money online casino

2025-03-26上午4:04

My developer is trying to persuade me to move to .net from PHP.

I have always disliked the idea because of the expenses.

But he’s tryiong none the less. I’ve been using Movable-type on a variety of websites for about a year and am worried about switching to another platform.

I have heard excellent things about blogengine.net.

Is there a way I can import all my wordpress posts into it?

Any help would be greatly appreciated!

My web page: primebiome reviews and complaints

2025-03-26上午10:04

I am genuinely grateful to the holder of this website who has shared this impressive

post at at this place.

Review my web-site :: esta usa visa

2025-03-26下午12:44

This is a great article!

https://www.aljazeera.com/

2025-03-26下午6:57

Link exchange is nothing else however it is just placing the other person’s web site link on your page at appropriate

place and other person will also do similar for you.

My blog post: hair transplant turkey

2025-03-27上午6:30

This is a great article!

https://m.yelp.ch/biz/ecovia-turf-ransome

2025-03-27上午10:45

This is a great article!

https://www.yelp.com.tr/biz/ecovia-turf-ransome

2025-03-27下午2:27

This is a great article!

https://www.yelp.pl/biz/yb-painting-services-wooloowin-2

2025-03-27下午7:29

This is a great article!

https://m.en.yelp.be/biz/yb-painting-services-wooloowin-2

2025-03-28上午12:33

This is a great article!

https://m.yelp.pt/biz/yb-painting-services-wooloowin-2

2025-03-28上午6:48

This is a great article!

https://www.yelp.es/biz/yb-painting-services-wooloowin-2

2025-03-28下午4:28

This is a great article!

https://www.yelp.com.tr/biz/yb-painting-services-wooloowin-2

2025-03-28下午7:53

This is a great article!

https://www.yelp.it/biz/goodfellows-electrical-macgregor

2025-03-28下午11:38

When some one searches for his necessary thing, so he/she needs to be available that in detail, so that thing is

maintained over here.

my blog; esta usa visa

2025-03-29上午5:59

This is a great article!

https://www.nl.yelp.be/biz/goodfellows-electrical-macgregor

2025-03-29上午9:26

You’re so awesome! I do not suppose I have read through something

like that before. So nice to discover someone with original thoughts on this issue.

Really.. thanks for starting this up. This web site is something that is needed on the web, someone with some originality!

Feel free to surf to my web-site Косметология в Строгино

2025-03-29下午6:14

This is a great article!

https://www.yelp.dk/biz/goodfellows-electrical-macgregor

2025-03-30上午1:08

This is a great article!

https://m.yelp.nl/biz/goodfellows-electrical-macgregor

2025-03-30上午9:59

Fantastic blog! Do you have any helpful hints for aspiring writers?

I’m hoping to start my own site soon but I’m a little

lost on everything. Would you propose starting with a free platform like WordPress or go for a paid

option? There are so many options out there that I’m

totally confused .. Any suggestions? Thanks a lot!

Here is my web blog … best online casino uk

2025-03-30上午11:15

This is a great article!

https://www.yelp.cz/biz/aaa-city-removalist-sydney-bankstown

2025-03-30下午12:14

This is a great article!

https://www.yelp.com.au/biz/aaa-city-removalist-sydney-bankstown

2025-03-30下午4:45

This is a great article!

https://m.yelp.cl/biz/aaa-city-removalist-sydney-bankstown

2025-03-30下午9:44

This is a great article!

https://m.en.yelp.be/biz/melbourne-concrete-driveways-elwood-2

2025-03-31上午8:22

This is a great article!

https://www.yelp.com.ph/biz/melbourne-concrete-driveways-elwood-2

2025-03-31上午11:49

This is a great article!

https://m.yelp.com.mx/biz/melbourne-concrete-driveways-elwood-2

2025-03-31下午1:57

This is a great article!

https://m.yelp.com.sg/biz/gigantic-signs-kent-town

2025-04-01上午10:34

This is a great article!

https://m.yelp.de/biz/gigantic-signs-kent-town

2025-04-01下午2:46

This is a great article!

https://www.yelp.no/biz/gigantic-signs-kent-town

2025-04-01下午4:33

This is a great article!

https://www.yelp.com.sg/biz/gigantic-signs-kent-town

2025-04-01下午11:31

This is a great article!

https://www.yelp.pt/biz/gigantic-signs-kent-town

2025-04-02上午10:34

This is a great article!

https://m.yelp.com.tr/biz/gigantic-signs-kent-town

2025-04-03上午12:42

gcgbfq

2025-04-03上午5:38

This is a great article!

https://m.yelp.es/biz/gigantic-signs-kent-town

2025-04-03上午10:40