Crane Stabilizer Pads

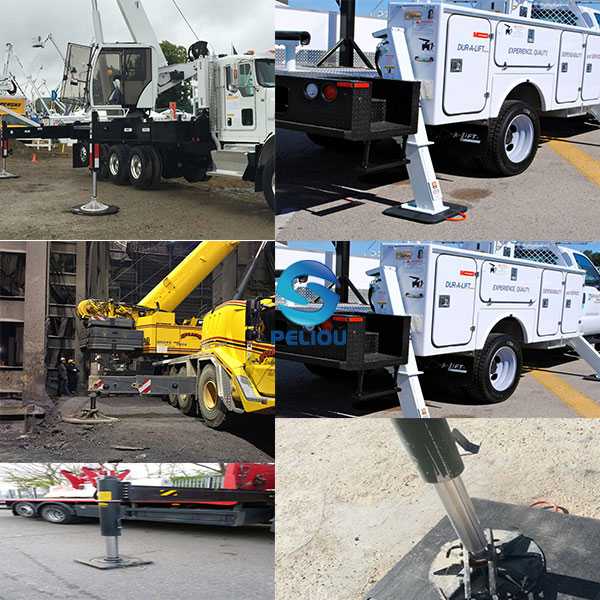

431In most construction environments, especially in the application scenarios of construction sites, safety is a key and very important factor.

View detailsSearch the whole station HDPE ground protection mats Video 产品分类菜单

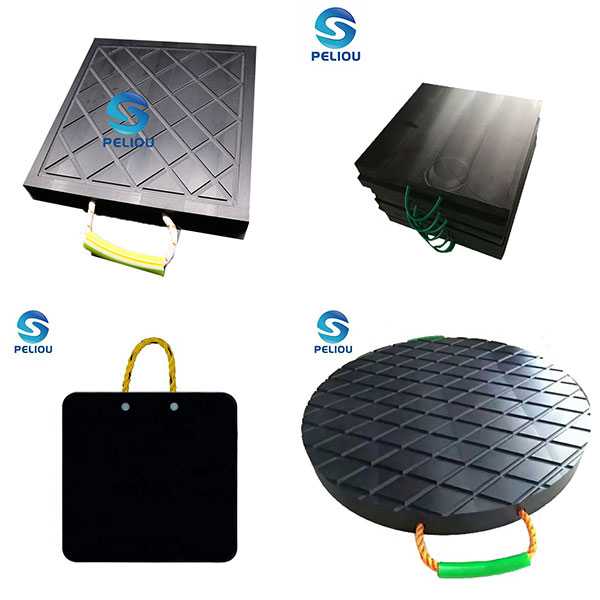

Outrigger PADS are composed of a plate-like pad body and a hand-held rope. The plate body is made of UHMWPE polymer synthetic material or MC nylon. PE polymer synthetic material backing plate four corners support 60mm pressure 15-18 tons /cm above, can be used normally in bad environment, the use of overloading rather than bending fracture. The rope is made of nylon and the end of the rope is embedded in outrigger pads for easy transport and placement. MC nylon pressed Outrigger pads have strong pressure bearing capacity, which can reach 30-45 tons /cm or more.

Ultra-high molecular weight polyethylene material pressed Outrigger pads have a stronger bearing capacity, up to 10-300 tons.

Product performance: wear resistance, impact resistance, chemical corrosion resistance, low temperature wear resistance coefficient, light weight, energy absorption, aging resistance, flame retardant, antistatic, etc.

Product specifications: common specifications 450*450mm, 500*500mm, 550*550mm 600*600 mm, also can be produced on request.

Outrigger PADS color: generally black and yellow, can also be made according to requirements.

Advantages:

Outrigger Pads are unique industry preferred safety accessories for pump trucks to reduce outrigger slip problems. Even in the case of uneven road surface, it can ensure safe use. Waterproof; No weight gain, no increased risk of failure due to water absorption or frost. Improve the performance and life of ouster plate.

In most construction environments, especially in the application scenarios of construction sites, safety is a key and very important factor.

View detailsPeliou's protective pad products are exported to the global ground protection mats market and provide one-stop after-sales service.

View detailsUhmwpe material can not only be used as ground mat, but also as sheet , which has a wider range of uses

View details

the senior New York senator told the Daily News buying propecia online

2025-01-17下午7:42

With havin so much content do you ever run into any problems

of plagorism or copyright violation? My site has a lot of unique content I’ve either authored myself or outsourced but it

looks like a lot of it is popping it up all over the web

without my authorization. Do you know any techniques to help prevent content from being stolen? I’d genuinely appreciate it.

Feel free to visit my web blog :: диплом о высшем образовании

2025-02-06下午9:27

Hey there! I know this is kinda off topic nevertheless I’d figured I’d ask.

Would you be interested in exchanging links or maybe guest authoring

a blog post or vice-versa? My blog discusses a lot of the same subjects as yours and I think we could greatly benefit from each other.

If you are interested feel free to send me an e-mail.

I look forward to hearing from you! Terrific blog by the way!

Also visit my web blog: Crypto Loko Casino no deposit bonus

2025-02-16下午4:48

qyydpr

2025-03-06下午9:47